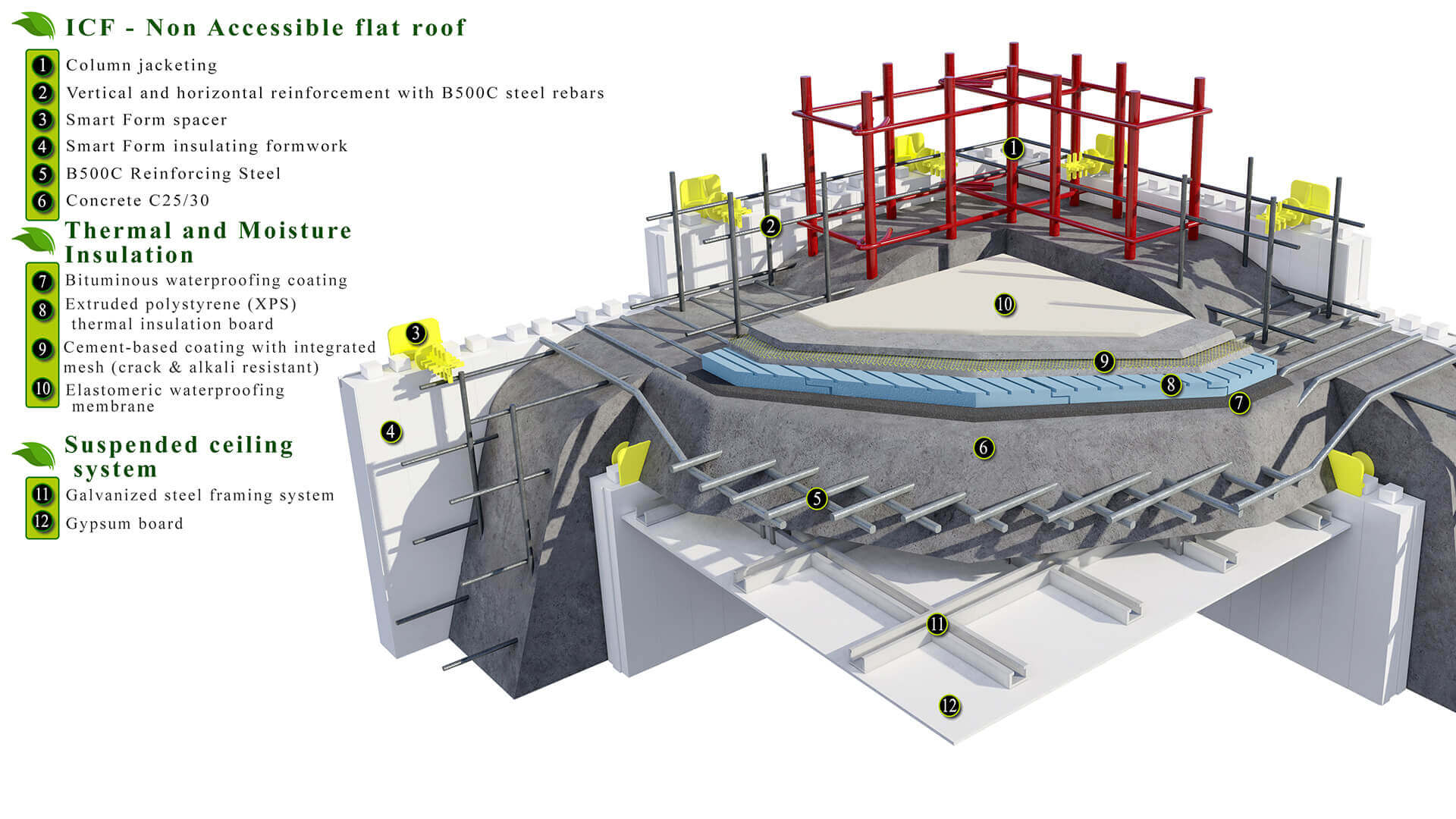

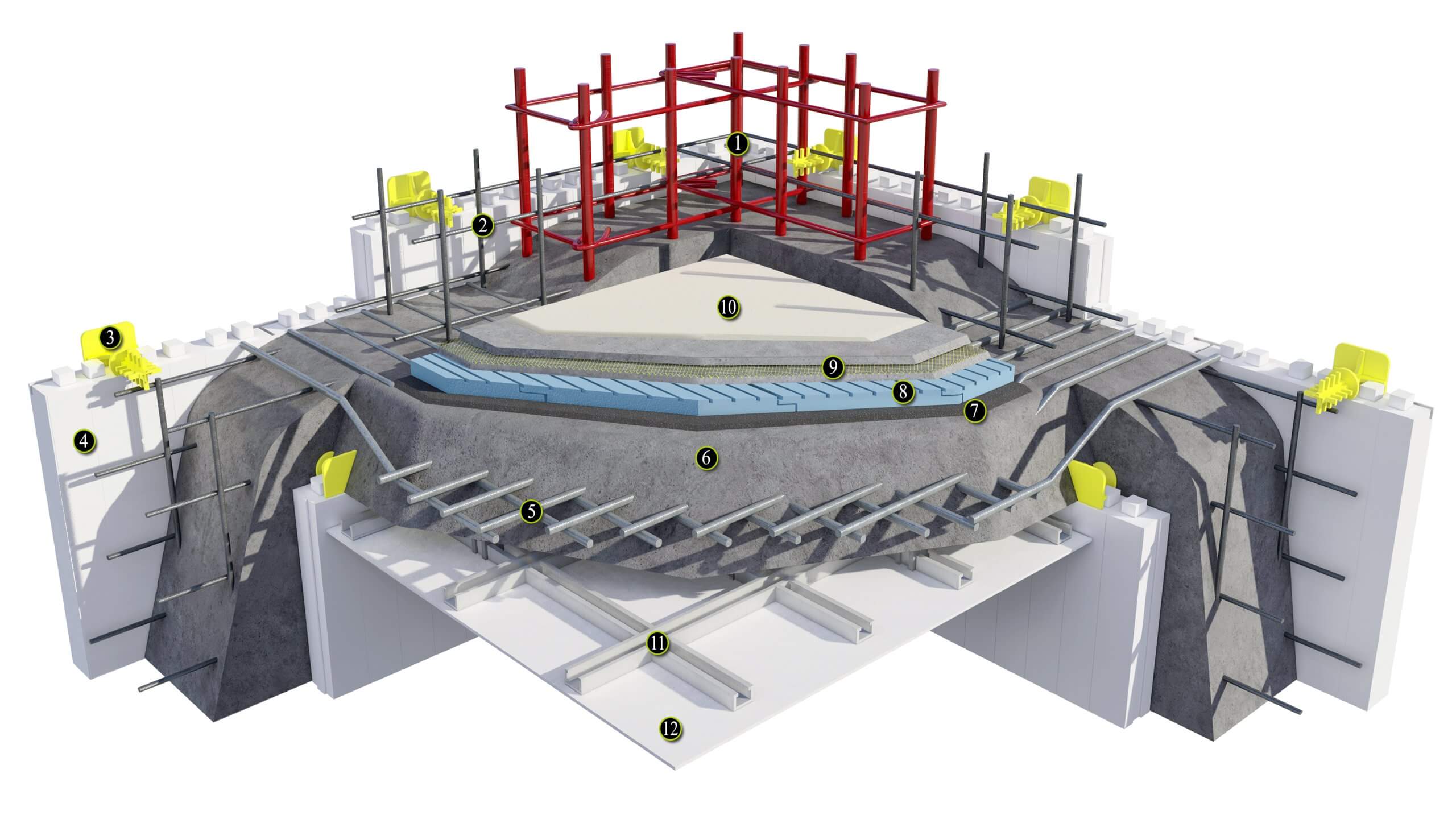

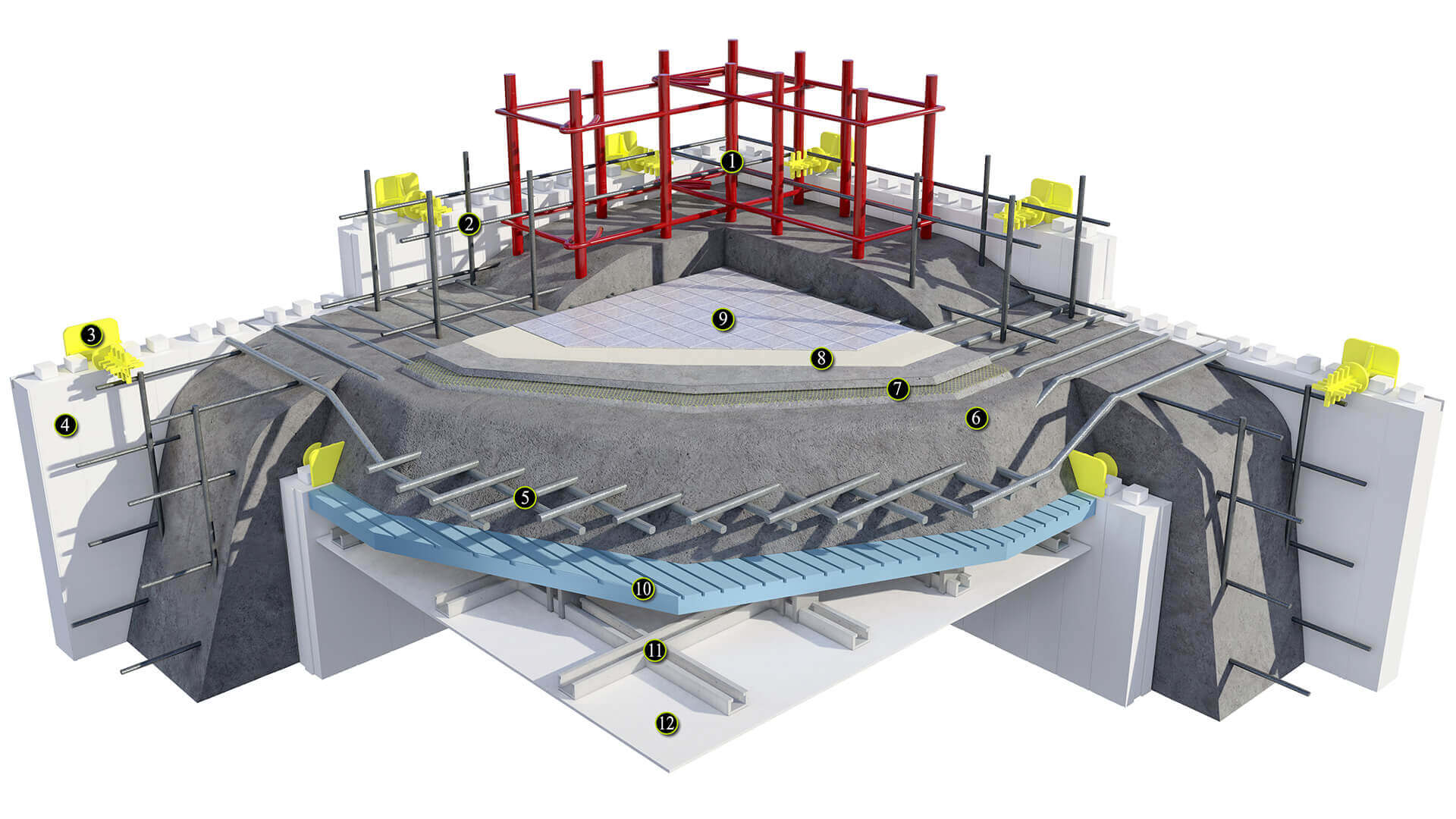

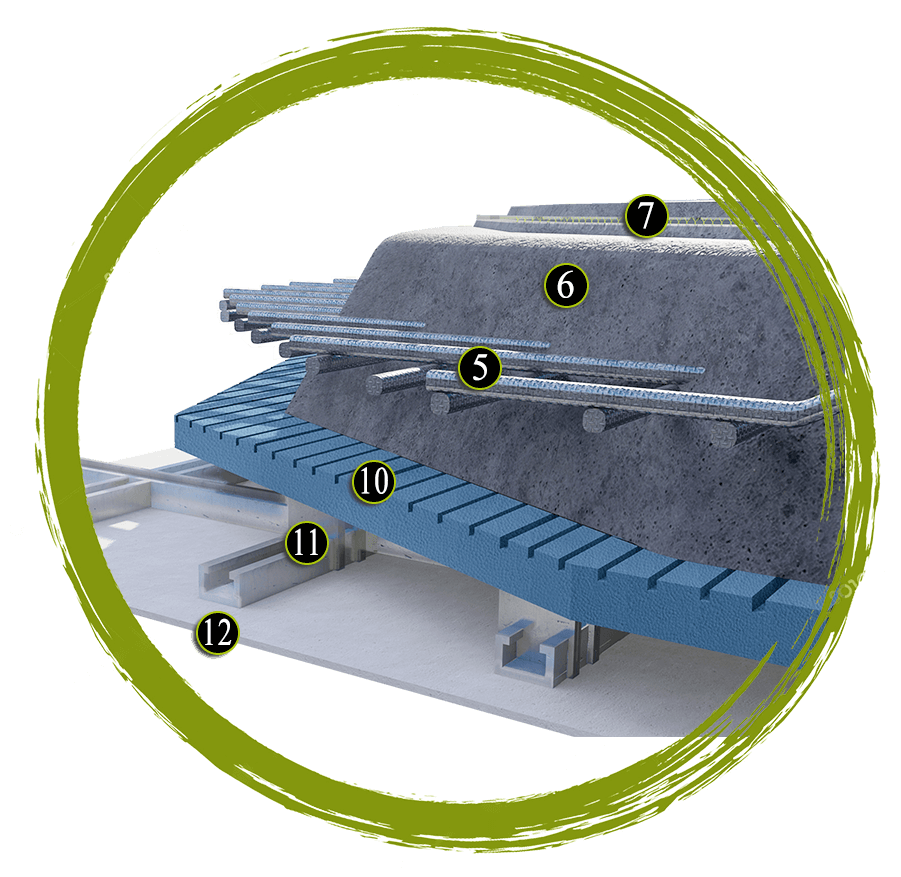

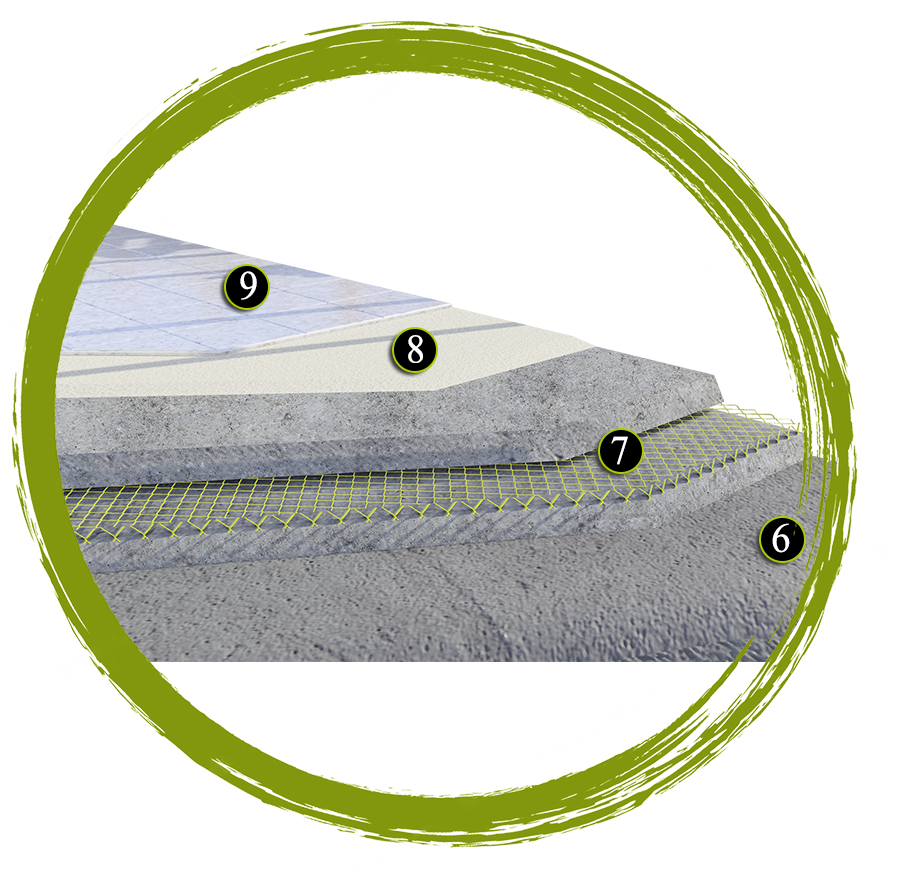

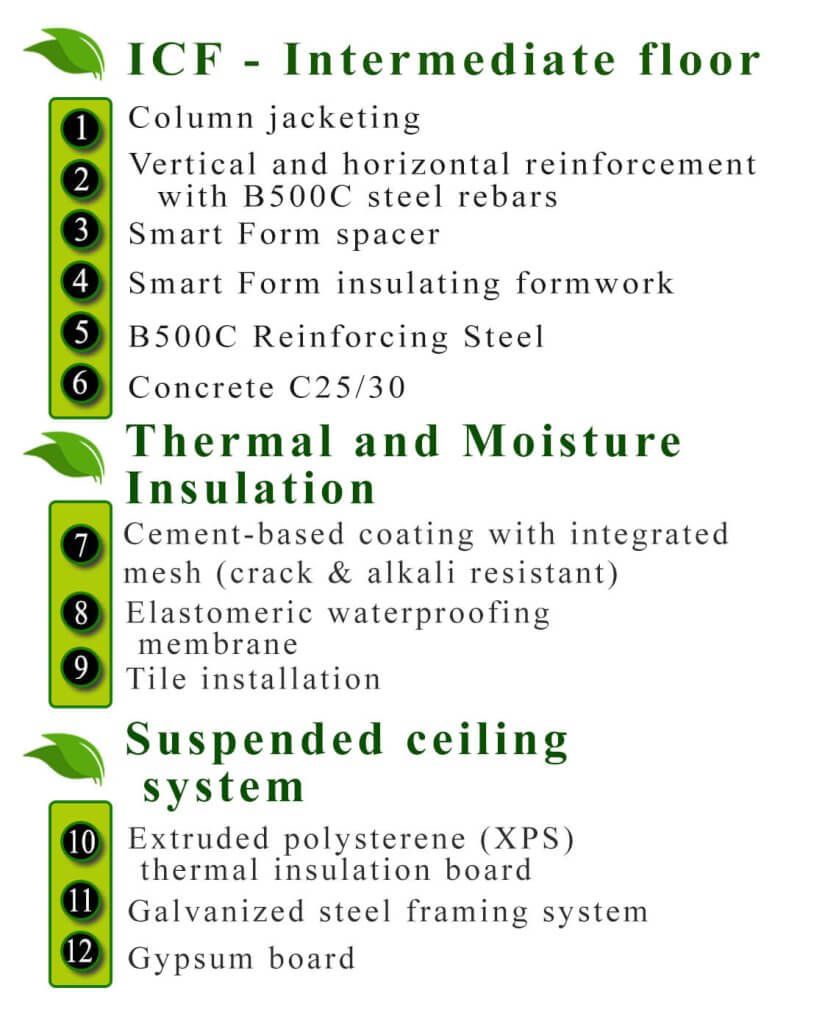

ICF is a high-performance thermal insulating formwork that replaces traditional timber formwork and consists of two sheets of expanded polystyrene EPS 250 with a thickness of 8.20 cm.

The insulating forms are assembled on site, installed in a staggered arrangement, and connected to each other using PVC spacers, which are placed on the sheets, forming a rectangular cavity of 25 cm.

This cavity is then reinforced with B500C steel, according to the structural requirements, and finally poured with C25/30 concrete.

WHY ICF IS THE FUTURE OF CONVENTIONAL CONSTRUCTION

WHY ANDROULAKIS ICF

We use expanded polystyrene EPS 250.

We use greater thickness (8.20 cm), thus providing the best thermal insulation coefficient in its category.

We use greater length (1.20 m).

Androulakis ICF technology corresponds to Energy Class A homes, and the energy classification of ICF residences is determined by the calculation software of the regulation (KENAK).

See here detailed construction materials, information, and their characteristics.

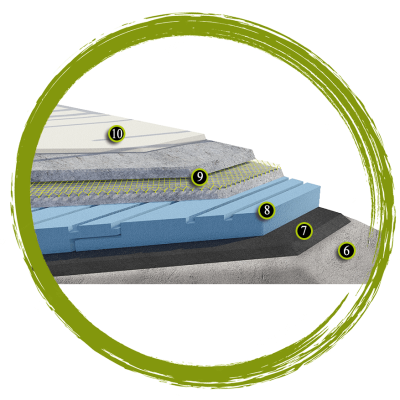

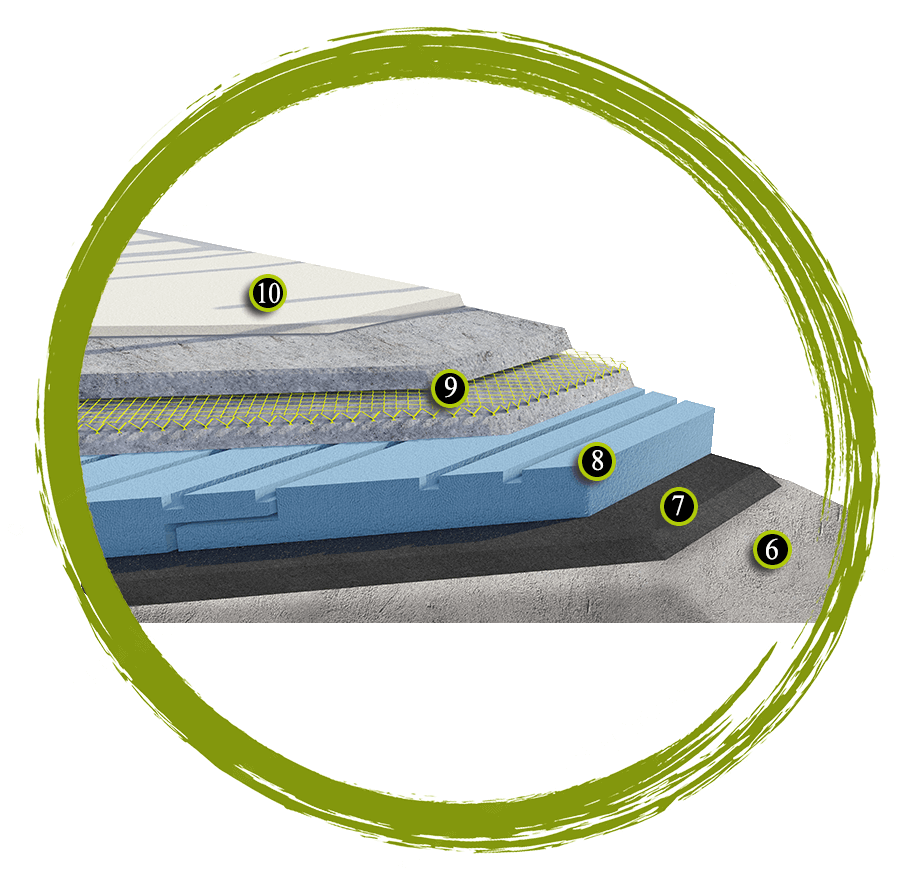

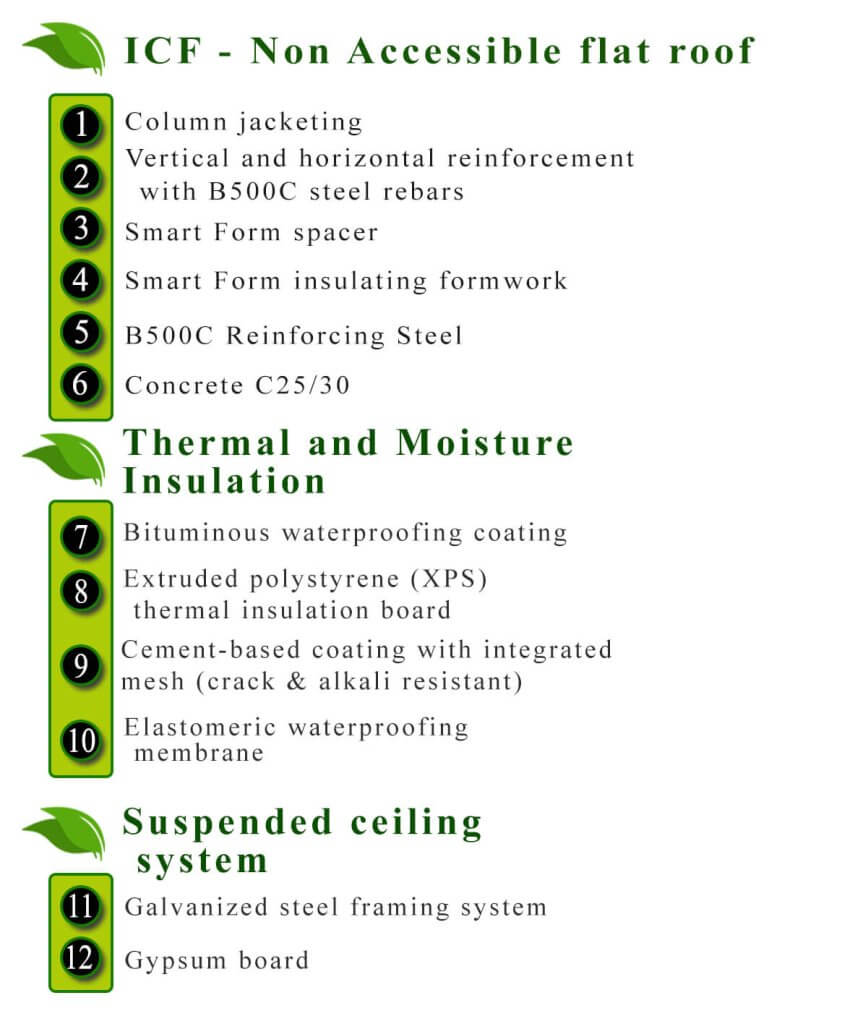

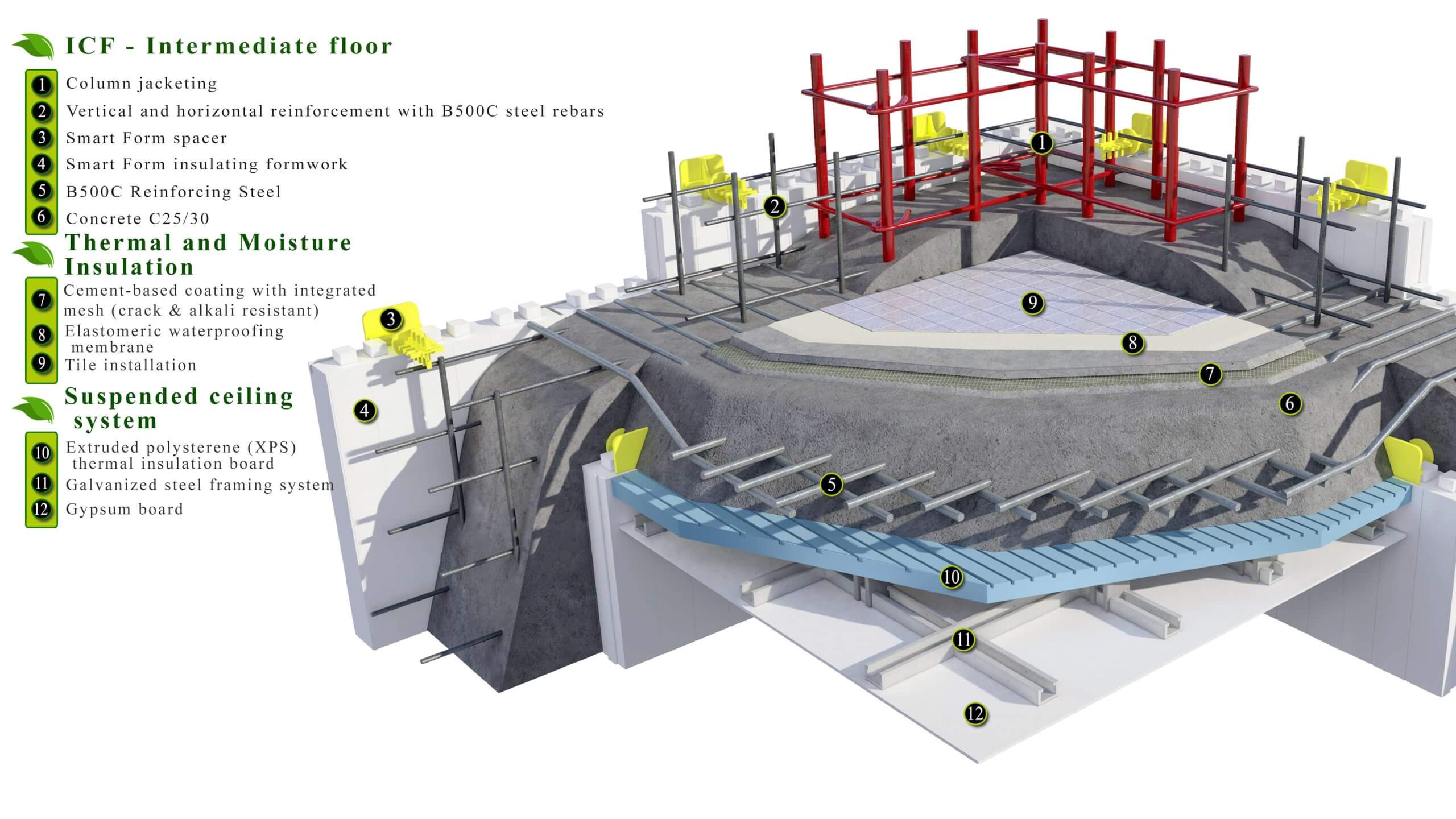

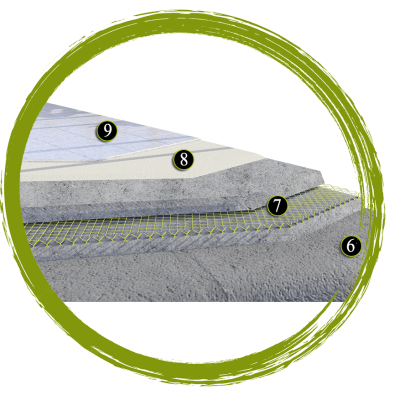

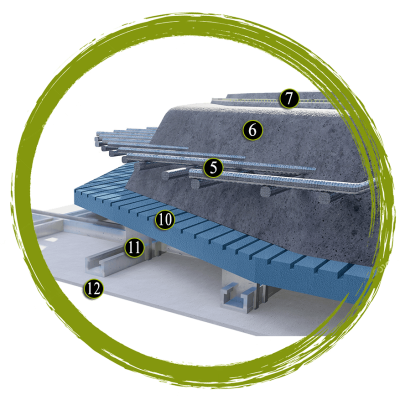

The most modern energy system that accompanies the Eco Smart Form System technology of Androulakis incorporates the finest construction materials available on the global market:

See here detailed construction materials, information, and their characteristics.

The most modern energy system that accompanies the Eco Smart Form System technology of Androulakis incorporates the finest construction materials available on the global market:

See here detailed construction materials, information, and their characteristics.

The most modern energy system that accompanies the Eco Smart Form System technology of Androulakis incorporates the finest construction materials available on the global market:

See here detailed construction materials, information, and their characteristics.

Androulakis ICF technology corresponds to Energy Class A homes.

The company has integrated control stages into the construction and completion of the project (Structural Study, Simulator, Air Tightness Test), which confirm the A+ classification and secure the high energy independence of the residence.

Energy Class A has gradations.

A green building residence with the same energy class (Class A+) as another may have significant differences in the level of required energy performance.

The classification of ICF residences is determined by the calculation software of the regulation (KENAK).

As a reference and for comparison, an ideal building of Energy Class B with specific insulation and technical characteristics is used.

We therefore compare the examined residence with this ideal building, and depending on the comparisons, the energy class category and its percentage grading are determined:

Class A+: 67% lower consumption than Class B

Class A: 50% – 67% lower consumption than Class B

Class B+: 25% – 50% lower consumption than Class B

Class B: 0% – 25% lower consumption than Class B

ICF residences of our company, taking into account individual factors such as design, location, and the microclimate of the area, are classified in Energy Class A and meet the requirements set by the Passive House Institute.

* The energy requirements of the residences are calculated based on total primary energy consumption for heating, cooling, and domestic hot water.

* The exact grading and calibration of the residence result after the completion of control and testing stages.