We undertake all necessary studies and procedures for the issuance of Building Permits with responsibility & consistency, whether for new construction or additions to existing buildings, etc.

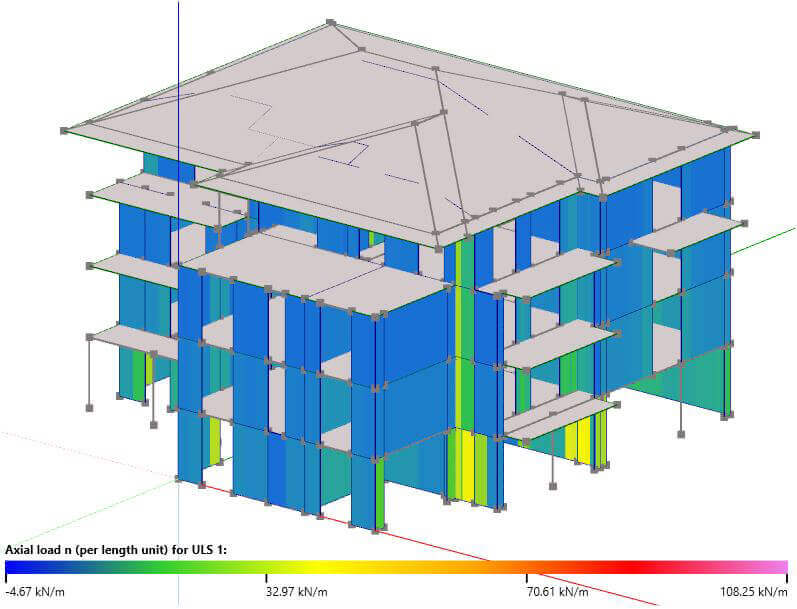

Having the appropriate expertise, technological resources, experience, as well as a reliable, integrated, and extensive in-house design department, we cover a wide range of studies.

Indicatively:

Topographical Studies, Architectural Studies, Structural Studies, Mechanical Engineering Studies, Heating & Cooling Studies, Fire Safety Studies, Natural Gas Studies, Environmental Studies

Project supervision from commencement through to completion