The primary purpose of reinforcing steel is the strength and stability of the structure, especially in cases of intense seismic activity. The B500c reinforcing steels used by our company are of Greek origin, of excellent quality, and manufactured according to modern specifications. They are distinguished by outstanding properties of strength, ductility, flexibility, and weldability, in accordance with strict anti-seismic regulations.

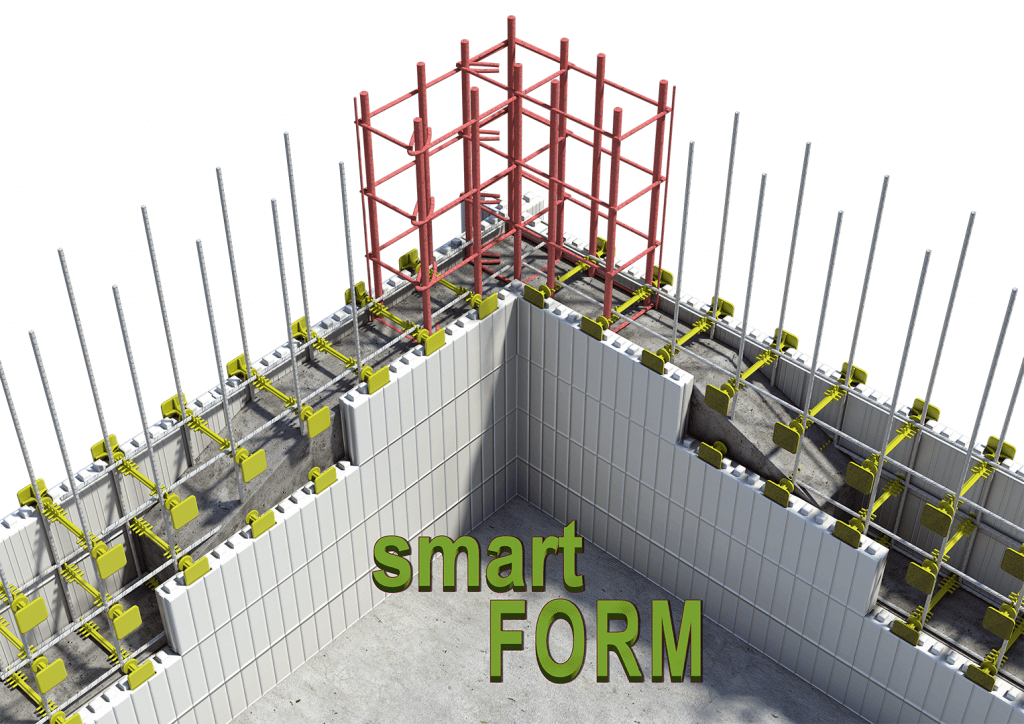

Reinforcing steel (columns – jackets, meshes) strengthens the load-bearing structure (frame) of the building and prevents the concrete from breaking or cracking at critical points such as columns, beams, slabs, etc.

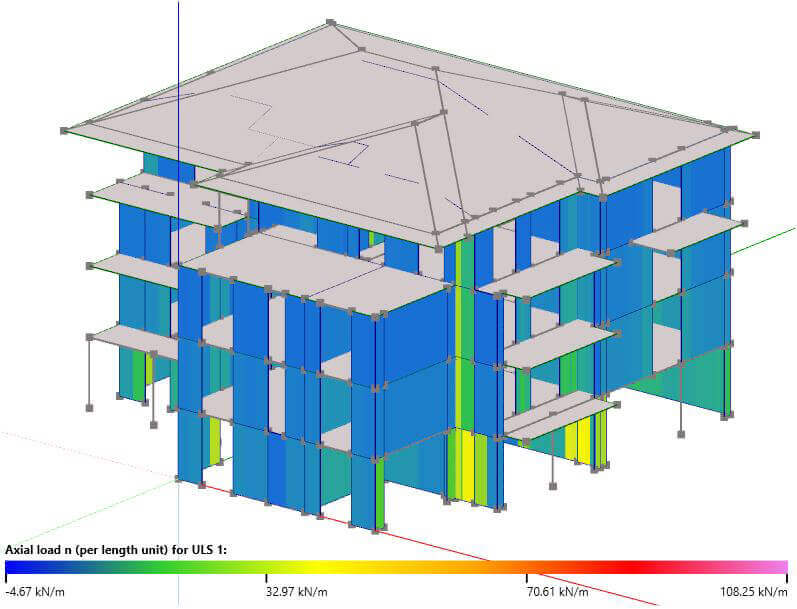

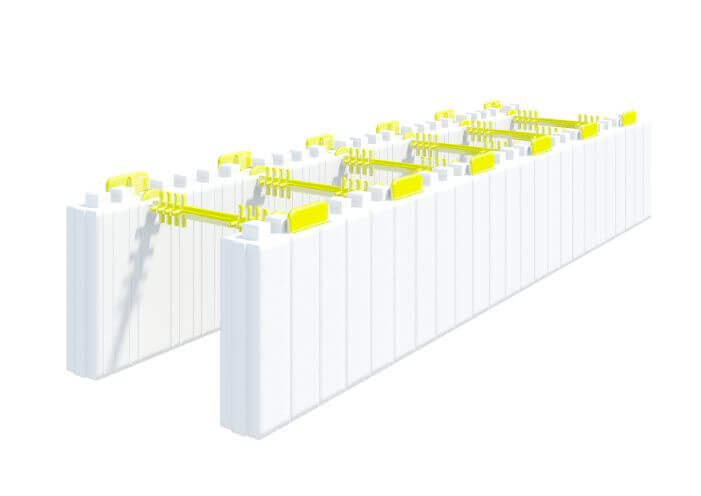

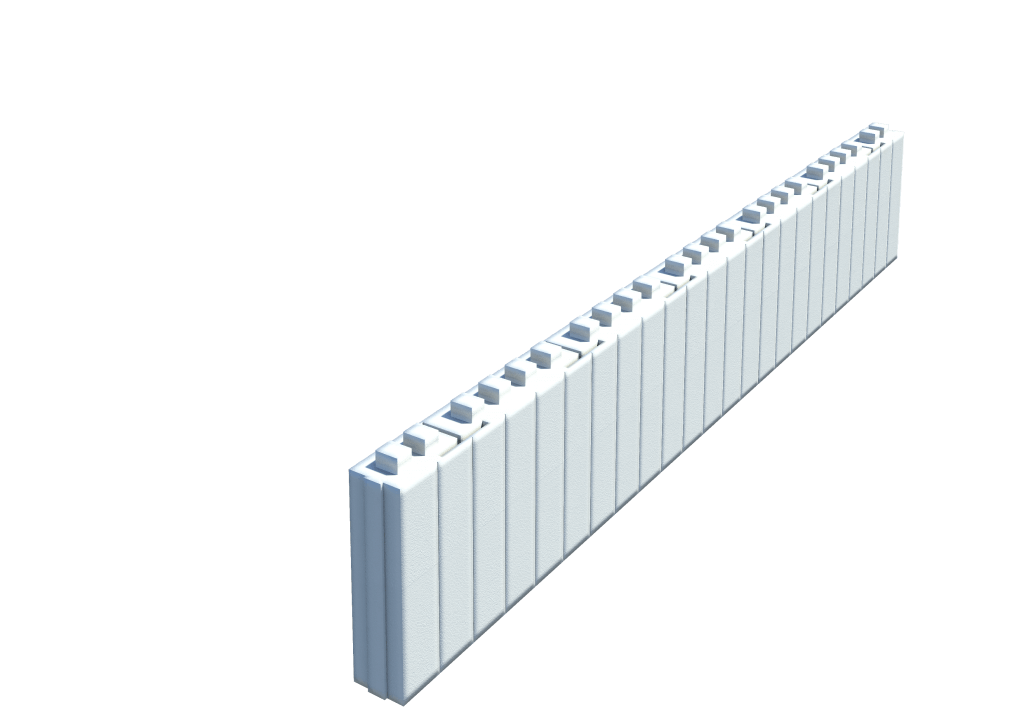

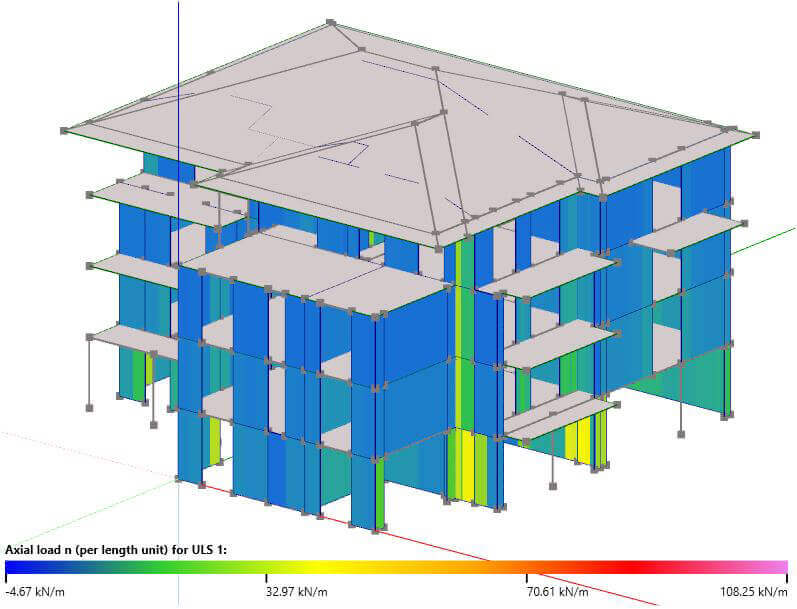

Due to the high seismicity of our country, the structural study of the building is strictly adhered to, and in combination with the use of the ANDROULAKIS insulating formwork, which allows for a fully reinforced concrete building, the residence is rendered fully earthquake-resistant, capable of withstanding successive seismic vibrations with various accelerations (g: 0.5 to 0.9) and different directions.