ICF STRUCTUAL ELEMENTS OF ANDROULAKIS

Below you can see detailed information about the building materials used in the constructions we apply at Androulakis, as well as their characteristics and technology.

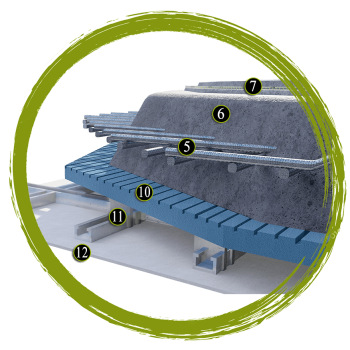

ANDROULAKIS ICF MASONRY

B500c steel of Greek origin.

The B500c reinforced concrete steel is the primary material ensuring the safety and strength of a reinforced concrete construction. Its main purpose is to provide resistance and stability to the structure, especially in cases of intense seismic activity.

The reinforcement steel (bars, meshes) strengthens the building’s load-bearing frame and prevents the concrete from cracking or breaking at critical points such as columns, beams, and slabs.

During seismic activity, the steel absorbs seismic energy and prevents damage to the building.

Due to the high seismicity of the region, strict adherence to the structural engineer’s study is required, along with the use of high-strength and ductile steel, according to ELOT 1421 standards.

The B500c steel used by the company is sourced from the Greek company SIDENOR, of excellent quality, meeting modern specifications, and is distinguished by its strength, ductility, flexibility, and weldability, in accordance with anti-seismic regulations and the new ELOT 1421 standard.

B500c steel of Greek origin.

The B500c reinforced concrete steel is the primary material ensuring the safety and strength of a reinforced concrete construction. Its main purpose is to provide resistance and stability to the structure, especially in cases of intense seismic activity.

The reinforcement steel (bars, meshes) strengthens the building’s load-bearing frame and prevents the concrete from cracking or breaking at critical points such as columns, beams, and slabs.

During seismic activity, the steel absorbs seismic energy and prevents damage to the building.

Due to the high seismicity of the region, strict adherence to the structural engineer’s study is required, along with the use of high-strength and ductile steel, according to ELOT 1421 standards.

The B500c steel used by the company is sourced from the Greek company SIDENOR, of excellent quality, meeting modern specifications, and is distinguished by its strength, ductility, flexibility, and weldability, in accordance with anti-seismic regulations and the new ELOT 1421 standard.

Concrete C25/30

Characteristics:

Resistant to various aggressive exposure environments.

Excellent mechanical strength

Excellent compressive and tensile strength

High quality and durability

Reduced water permeability, ideal for coastal environments

Resistant to surface wear

Resistant to chemical attacks

The strict provisions of the Concrete Technology Regulation of 1997 (C.T.R. 97) specify the minimum dosages of raw materials depending on the specific application of the concrete (such as workability, strength, plasticity, exposure environment, performance, and service life of the construction). The different properties of the raw materials mixed in concrete production (mass, volume, physico-chemical characteristics) make concrete production an extremely complex and sophisticated process.

Due to the high seismic activity in our country, both the production process and the final incorporation of the concrete into constructions are governed by the highly demanding Concrete Technology Regulation (C.T.R. 97), which is currently in effect, covering the requirements for modern, safe, and earthquake-resistant constructions.

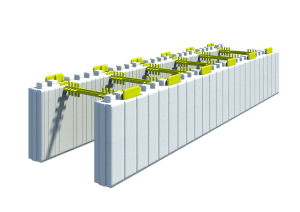

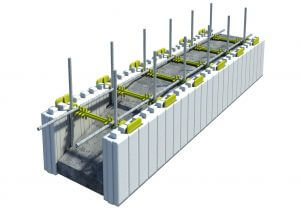

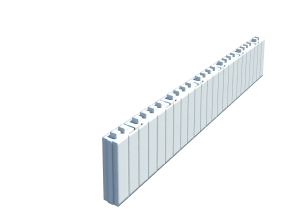

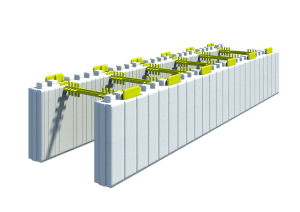

PVC is harder and more durable than steel and can withstand very low and very high temperatures.

PVC is a thermoplastic polymer and can produce products with a wide range of mechanical properties (from flexible to rigid), has chemical resistance, and is difficult to ignite.

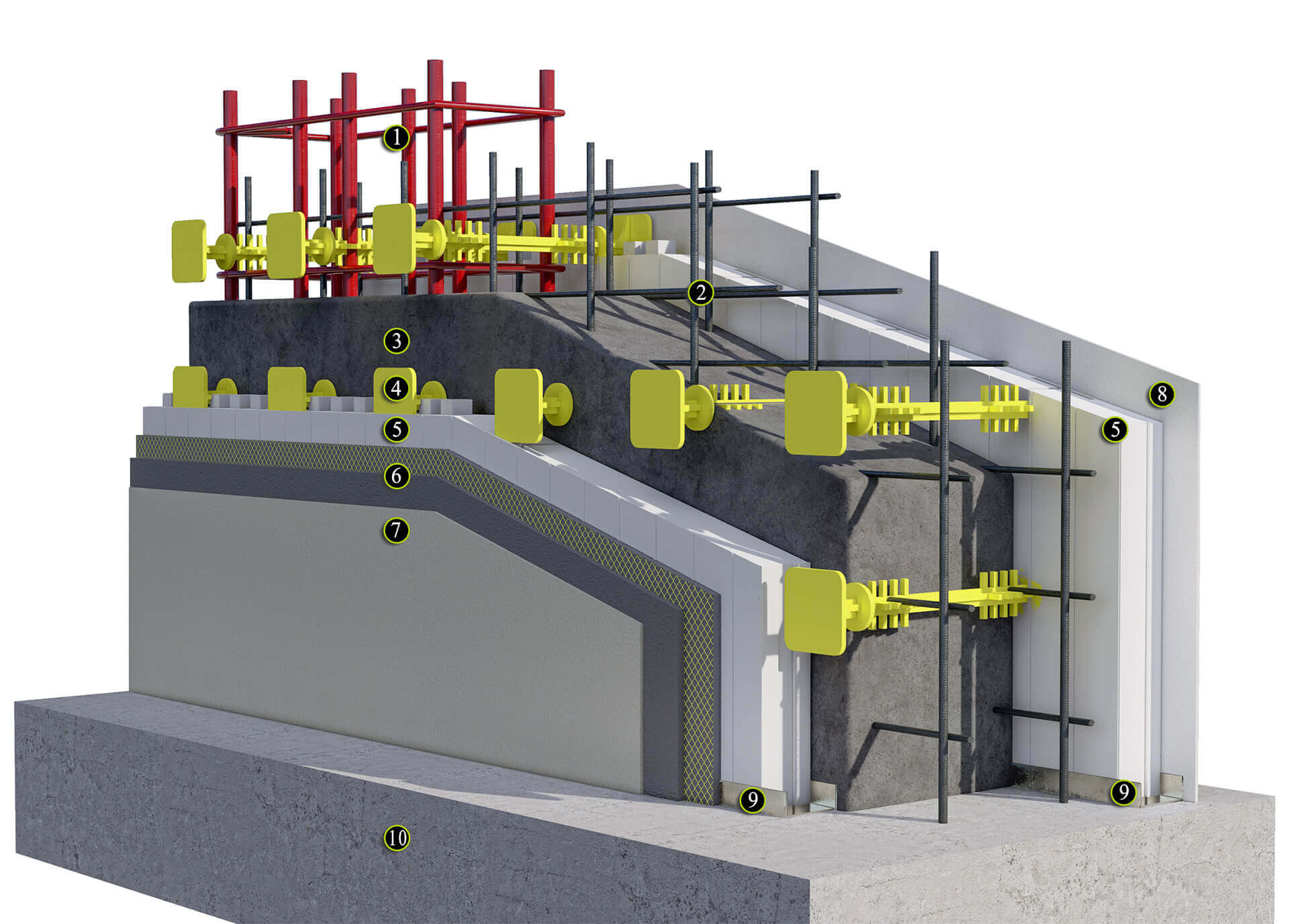

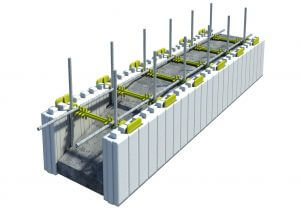

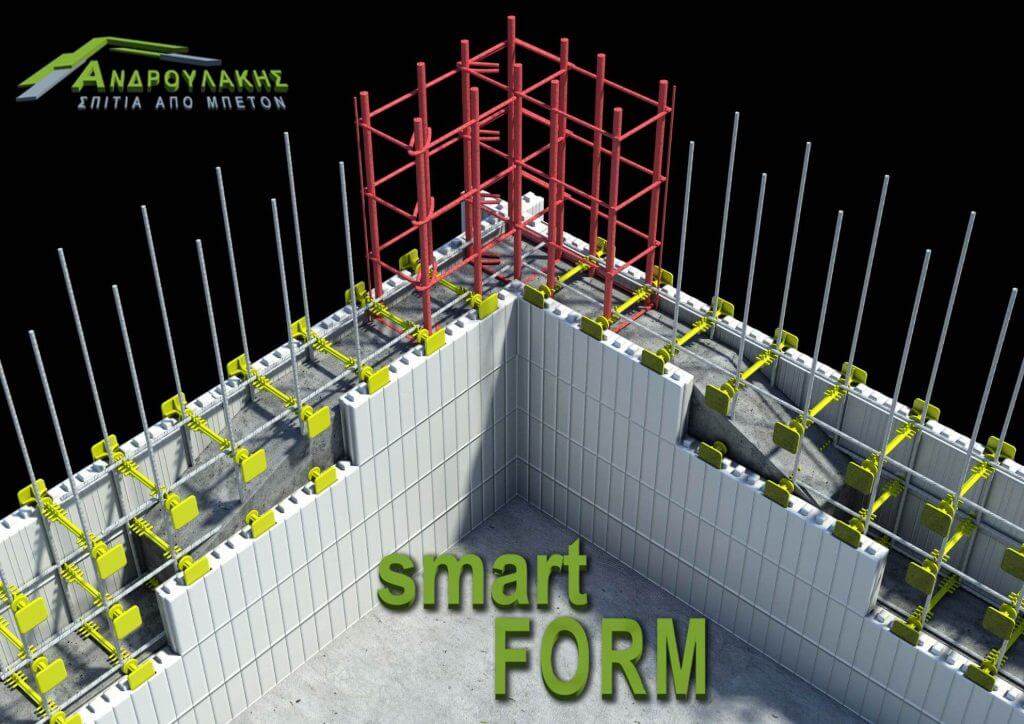

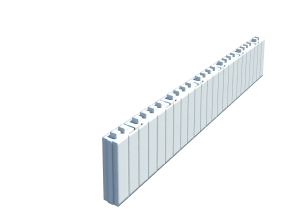

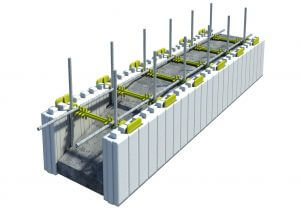

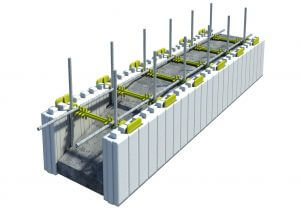

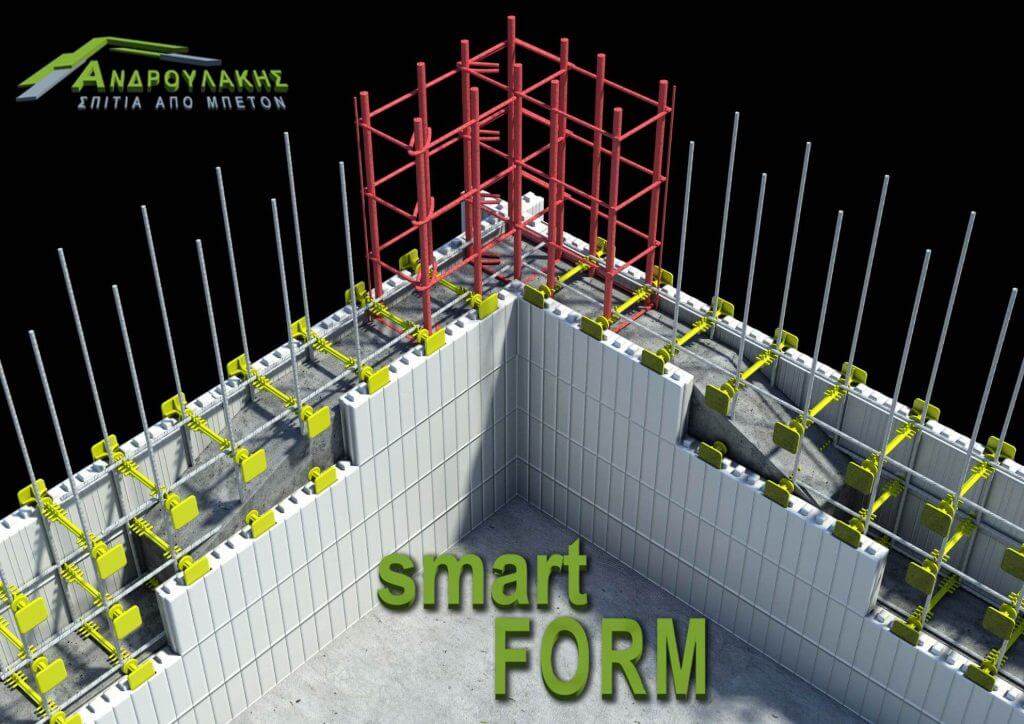

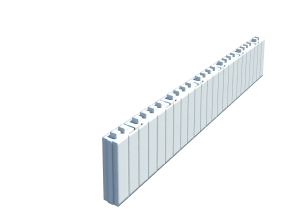

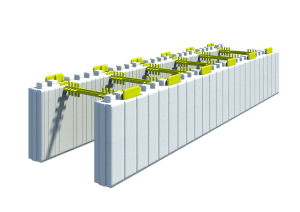

Smart Form is a material produced from solid polystyrene beads. It is rigid, environmentally friendly, has excellent thermal and acoustic insulation properties, is resistant to moisture, does not decompose, and consequently has a lifelong durability.

The ICF formwork provides double insulation for the building and remains as permanent formwork. Therefore, there is no need to wait for the concrete to harden, which significantly reduces construction time.

The ICF formwork technology also enables us to construct a building entirely from reinforced concrete, making the structure monolithic, solid, unified, and resistant to high seismic activity.

Characteristics:

Exceptional density

Self-extinguishing material (does not propagate flames)

Manufactured according to European standards EN 13163

Thermal insulation

Acoustic insulation

Environmentally friendly

Base Coat: Kappa 11 by BAUER.

It provides exceptional adhesion, high resistance to shear stress, and ensures superior durability.

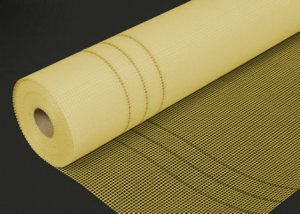

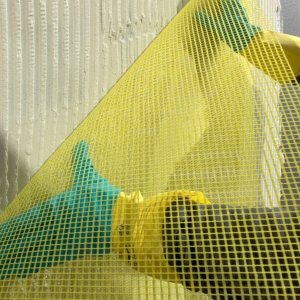

FIBERGLASS MESH

Characteristics:

Alkali-resistant

Crack-resistant

Alkali-resistant mesh for the base layer of the external thermal insulation system made of fiberglass. Complies with the European guideline ETAG 004.

User- and environmentally-friendly. High tensile strength. Strong resistance to elastic deformation, slippage, and displacement.

Final coat with a thickness of 5 mm, made of colored, fiber-reinforced inorganic material MONOKAPA by BAUER. It serves as the finishing layer of the Androulakis thermal insulation system.

Properties:

Water vapor permeability: V2 EN 7783-2

Water absorption: W3 EN 1062-3

Thermal conductivity: λ = 0.7 W/(m·K) EN 1745

It has high elasticity, minimizing the appearance of cracks, and excellent breathability. High resistance to algae and bacteria, as well as strong durability against rain. Exceptional performance under all weather conditions and UV exposure. Available in a wide range of colors with high color stability.

KNAUF PLASTERBOARD – INTERNAL WALL CLADDING MADE OF NATURAL GYPSUM

Application: Internal wall cladding for prefabricated houses or concrete houses, applicable to both load-bearing and non-load-bearing elements in dry construction systems.

Advantages:

Non-combustible, fire-resistant: Class A1

Breathable (water vapor permeability)

Flexible

Minimal expansion and contraction with changes in climatic conditions

Environmentally friendly due to natural gypsum raw material

Easy to work with and repair in case of damage

Provides thermal and acoustic insulation

Thermal conductivity: λ = 0.21 W/(m·K)

Sound absorption coefficient: A

Type: Plasterboard according to DIN 18180 GKB, EN 520 A, ELOT 784

Description:

Knauf plasterboard with λ = 0.21 W/(m·K), made from natural gypsum, porous and breathable, allowing the wall to “breathe.” Easy to repair if damaged. It is a modern material for interior construction, offering thermal insulation, acoustic insulation, and seismic resistance.

For bathrooms, a special moisture-resistant Knauf Guardex plasterboard is used, containing additives that reduce water absorption.

Thickness: 12.5 mm

Product Certification: EN 520:2004 + A1:2009, complying with German standard DIN 18180, European EN 520, and Greek ELOT 784

WALL STARTING STRIPS

ANDROULAKIS ICF INTERIOR MASONRY

KNAUF PLASTERBOARD – INTERNAL WALL CLADDING MADE OF NATURAL GYPSUM

Application: Internal wall cladding for prefabricated houses or concrete houses, applicable to both load-bearing and non-load-bearing elements in dry construction systems.

Advantages:

Non-combustible, fire-resistant: Class A1

Breathable (water vapor permeability)

Flexible

Minimal expansion and contraction with changes in climatic conditions

Environmentally friendly due to natural gypsum raw material

Easy to work with and repair in case of damage

Provides thermal and acoustic insulation

Thermal conductivity: λ = 0.21 W/(m·K)

Sound absorption coefficient: A

Type: Plasterboard according to DIN 18180 GKB, EN 520 A, ELOT 784

Description:

Knauf plasterboard with λ = 0.21 W/(m·K), made from natural gypsum, porous and breathable, allowing the wall to “breathe.” Easy to repair if damaged. It is a modern material for interior construction, offering thermal insulation, acoustic insulation, and seismic resistance.

For bathrooms, a special moisture-resistant Knauf Guardex plasterboard is used, containing additives that reduce water absorption.

Thickness: 12.5 mm

Product Certification: EN 520:2004 + A1:2009, complying with German standard DIN 18180, European EN 520, and Greek ELOT 784

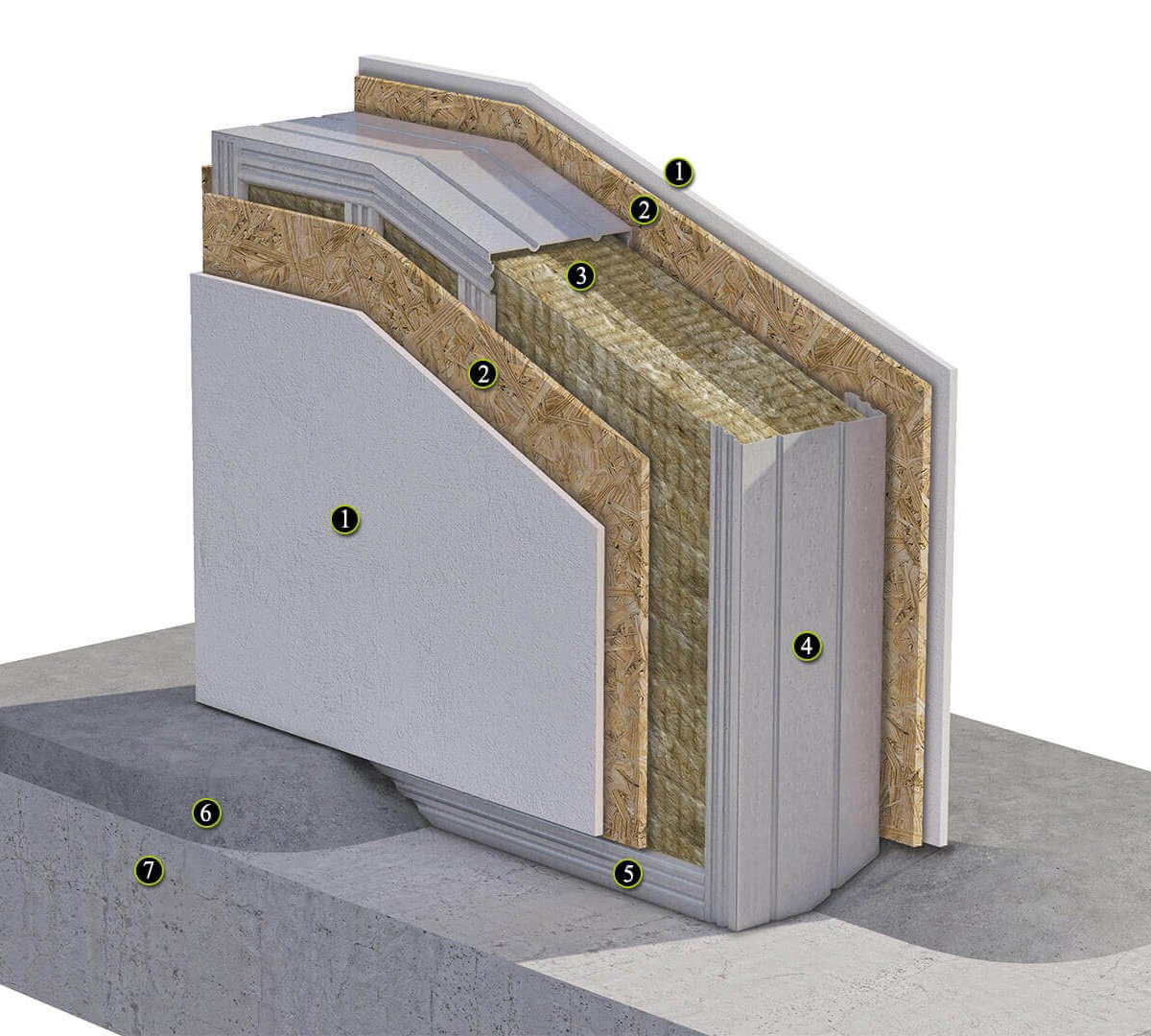

EGGER OSB 3 (Oriented Strand Board)

Description:

OSB – Oriented Strand Board, LP, λ = 0.13 W/(m·K), thickness: 11.1 mm, is an engineered wood material. Its uniformity makes it ideal for construction surfaces. OSB consists of long wood strands bonded together with a synthetic resin. The waterproof and high-temperature-resistant resin bonds combine with the wood strands to improve internal stability, rigidity, and moisture resistance.

Applications: Wall construction, intermediate floors, roofs

Among all structural elements of a building, the exterior walls are most exposed to changing weather conditions. Protection against summer overheating, thermal insulation in winter, and adequate sound insulation are reliably achieved with EGGER OSB 3.

Advantages of EGGER OSB 3:

Recommended for use in humid conditions (walls, intermediate floors, roofs)

Provides enhanced moisture resistance and safety against unexpected wetting, reducing the risk of warping or weakening of fastener connections

According to European standard EN 13986, classified as normally flammable, with moderate smoke emission and no flaming particles

Complies with Eurocode 5 requirements for external structural elements, such as exterior walls

Provides protection against fire and moisture

Higher density than plywood, ensuring longer lifespan

Fully waterproof (Class 3); the homogeneous structure ensures strong cohesion and resistance unaffected by moisture

Excellent thermal and acoustic insulation properties

High mechanical strength, contributing to improved structural stability of the building

Hygiene class: E1, recyclable and environmentally friendly

Meets European standard EN 300, with maximum mechanical strength, making it one of the best building materials available.

NATURAL MINERAL WOOL – ULTRACOUSTIC P HIGH SOUND ABSORPTION PARTITION BOARDS

Boards made of natural mineral wool, with high sound absorption, free of petroleum-based chemicals and formaldehyde. Resistant to microorganisms, bacteria, and mold.

Waterproof

Breathable (allows water vapor diffusion)

Applications: Thermal and acoustic insulation of partitions and walls, prefabricated houses, and ICF concrete houses.

Thermal conductivity: λ = 0.037 W/m·K

Non-combustible material, fire class: A1

Advantages:

Excellent fire resistance and Euroclass A1 rating

High mechanical strength

Superior acoustic performance

Thermal insulation, fire-protective, recyclable material

Certification: CE: MW-EN 13164-T4-AF5

In drywall constructions, the metal framework is the supporting system created from pre-formed metal profiles (usually galvanized steel) onto which the plasterboards are screwed.

This framework is responsible for transferring loads (weight of plasterboards, doors, cabinets, etc.), ensuring the mechanical stability of the construction, and providing geometric accuracy (flatness, vertical alignment, and level surfaces).

The metal profiles are intended for dry construction systems and are the ideal solution for false ceilings and partition walls using plasterboards. They offer corrosion resistance, long lifespan, and structural stability.

Components:

Horizontal profiles (guides – UW or UD depending on the application): Fastened to the floor, ceiling, and walls.

Vertical profiles (studs – CW or CD): Placed at regular intervals and connected to the horizontal guides.

Depending on the type of construction (wall, false ceiling, or wall cladding), different types and cross-sections of profiles are selected.

WALL STARTING STRIPS

Ο μεταλλικός σκελετός στις κατασκευές γυψοσανίδας είναι το σύστημα υποδομής που δημιουργείται από προδιαμορφωμένα μεταλλικά προφίλ (συνήθως γαλβανισμένου χάλυβα) πάνω στα οποία βιδώνονται οι γυψοσανίδες.

Ο σκελετός αυτός αναλαμβάνει να μεταφέρει τα φορτία (βάρος γυψοσανίδας, θυρών, ντουλαπιών κλπ.), να διασφαλίσει τη μηχανική σταθερότητα της κατασκευής και να προσφέρει γεωμετρική ακρίβεια (ισιότητα, κατακόρυφα, επίπεδα).

Τα μεταλλικά προφίλ προορίζονται για τα συστήματα ξηράς δόμησης και αποτελούν την απόλυτη λύση για τις κατασκευές ψευδοροφών και χωρισμάτων ξηράς δόμησης με την χρήση γυψοσανίδων. Προσφέρουν αντοχή στη σκουριά, μεγάλη διάρκεια ζωής και παρέχουν σταθερότητα στις κατασκευές.

Αποτελείται από:

Οριζόντια προφίλ (οδηγούς – UW ή UD ανάλογα με την εφαρμογή) που στερεώνονται στο δάπεδο, την οροφή και τους τοίχους.

Κάθετα προφίλ (στύλους – CW ή CD), που τοποθετούνται ανά τακτές αποστάσεις και συνδέονται στους οδηγούς.

Ανάλογα με το είδος της κατασκευής (τοίχος, ψευδοροφή, επένδυση τοιχοποιίας), επιλέγεται και διαφορετικός τύπος και διατομή προφίλ

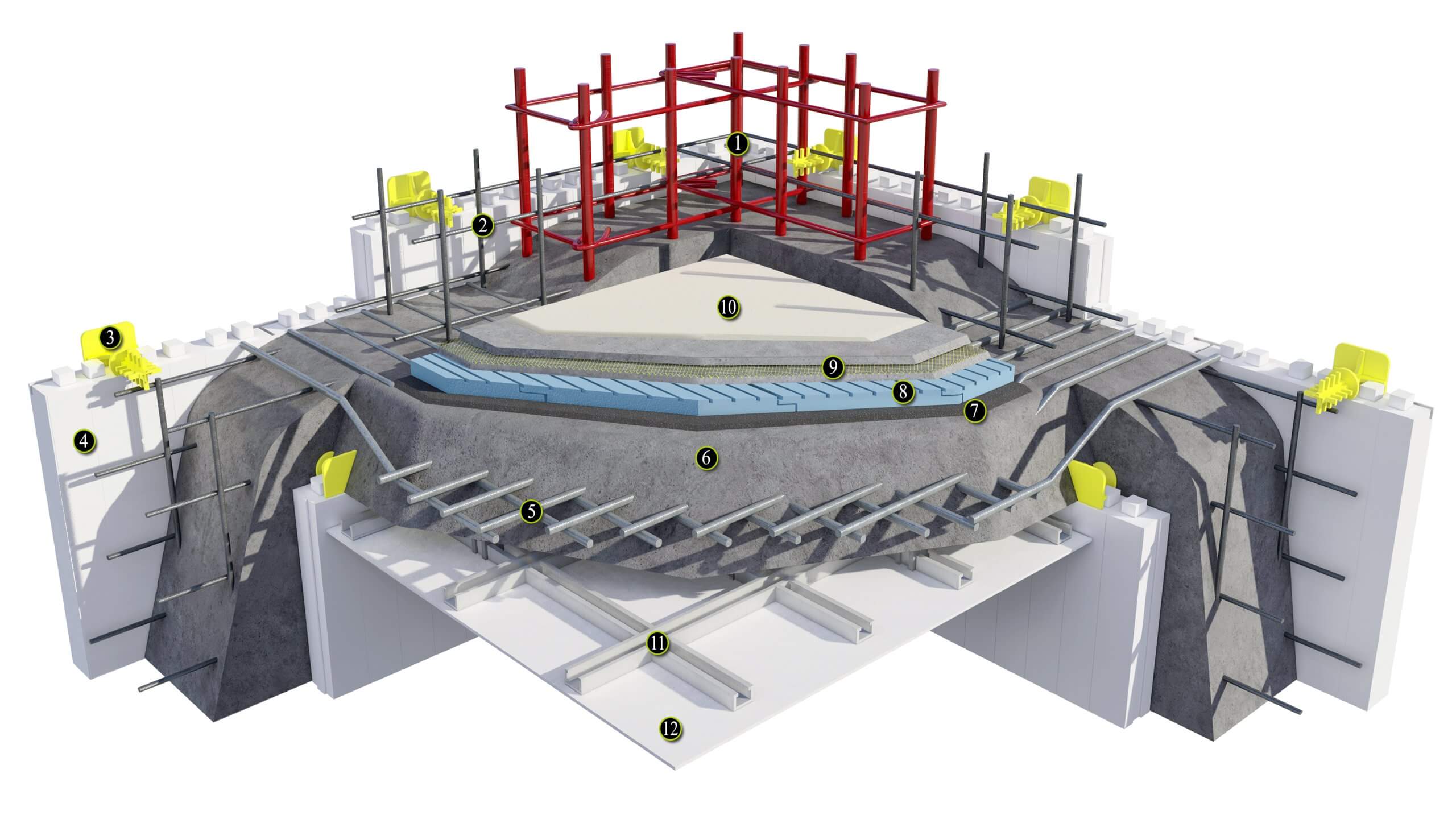

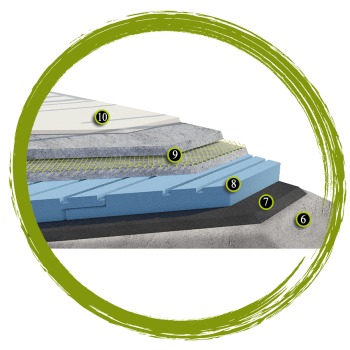

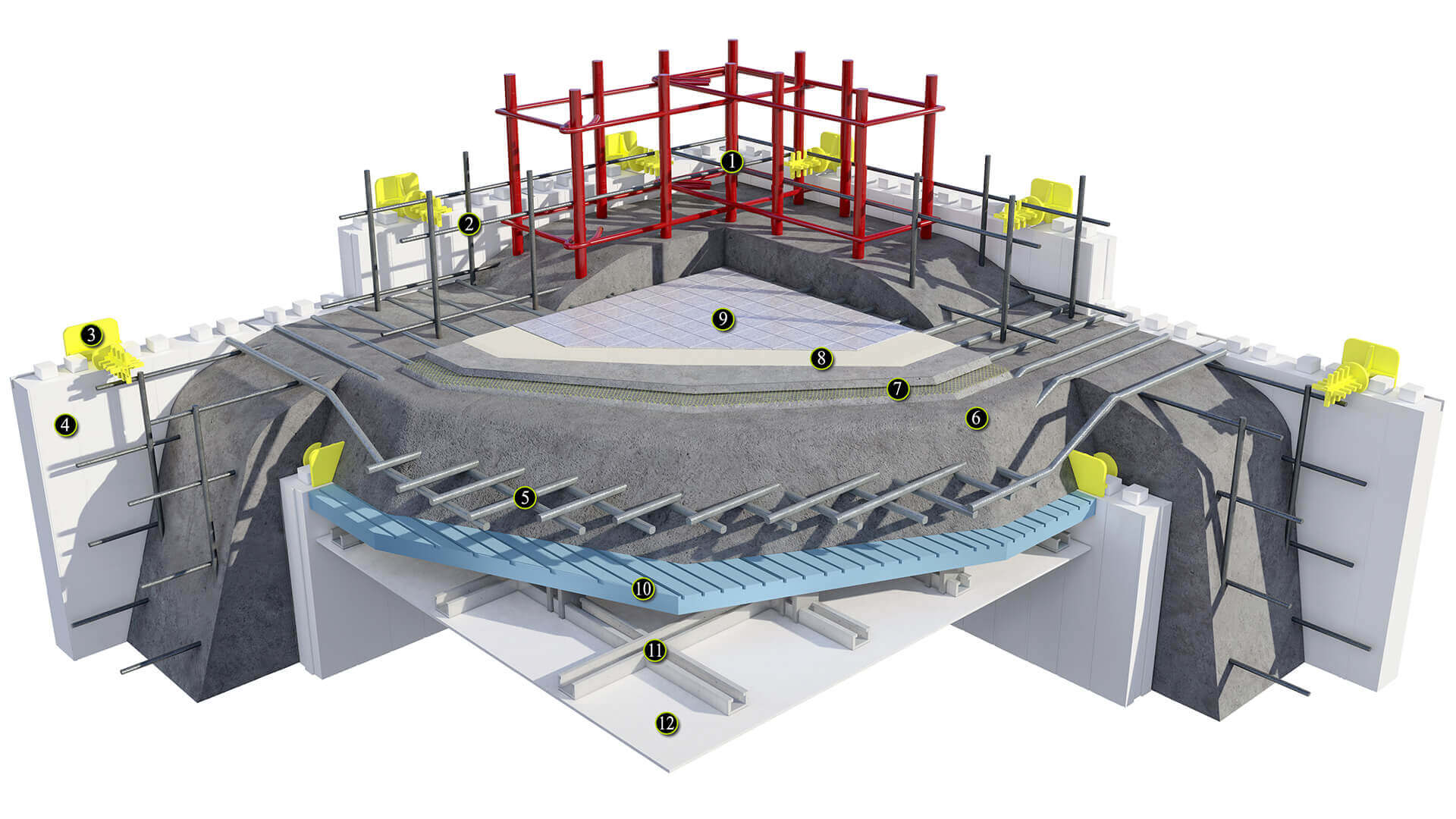

ANDROULAKIS ICF FLAT ROOF

B500c steel of Greek origin.

The B500c reinforced concrete steel is the primary material ensuring the safety and strength of a reinforced concrete construction. Its main purpose is to provide resistance and stability to the structure, especially in cases of intense seismic activity.

The reinforcement steel (bars, meshes) strengthens the building’s load-bearing frame and prevents the concrete from cracking or breaking at critical points such as columns, beams, and slabs.

During seismic activity, the steel absorbs seismic energy and prevents damage to the building.

Due to the high seismicity of the region, strict adherence to the structural engineer’s study is required, along with the use of high-strength and ductile steel, according to ELOT 1421 standards.

The B500c steel used by the company is sourced from the Greek company SIDENOR, of excellent quality, meeting modern specifications, and is distinguished by its strength, ductility, flexibility, and weldability, in accordance with anti-seismic regulations and the new ELOT 1421 standard.

B500c steel of Greek origin.

The B500c reinforced concrete steel is the primary material ensuring the safety and strength of a reinforced concrete construction. Its main purpose is to provide resistance and stability to the structure, especially in cases of intense seismic activity.

The reinforcement steel (bars, meshes) strengthens the building’s load-bearing frame and prevents the concrete from cracking or breaking at critical points such as columns, beams, and slabs.

During seismic activity, the steel absorbs seismic energy and prevents damage to the building.

Due to the high seismicity of the region, strict adherence to the structural engineer’s study is required, along with the use of high-strength and ductile steel, according to ELOT 1421 standards.

The B500c steel used by the company is sourced from the Greek company SIDENOR, of excellent quality, meeting modern specifications, and is distinguished by its strength, ductility, flexibility, and weldability, in accordance with anti-seismic regulations and the new ELOT 1421 standard.

PVC is harder and more durable than steel and can withstand very low and very high temperatures.

PVC is a thermoplastic polymer and can produce products with a wide range of mechanical properties (from flexible to rigid), has chemical resistance, and is difficult to ignite.

Smart Form is a material produced from solid polystyrene beads. It is rigid, environmentally friendly, has excellent thermal and acoustic insulation properties, is resistant to moisture, does not decompose, and consequently has a lifelong durability.

The ICF formwork provides double insulation for the building and remains as permanent formwork. Therefore, there is no need to wait for the concrete to harden, which significantly reduces construction time.

The ICF formwork technology also enables us to construct a building entirely from reinforced concrete, making the structure monolithic, solid, unified, and resistant to high seismic activity.

Characteristics:

Exceptional density

Self-extinguishing material (does not propagate flames)

Manufactured according to European standards EN 13163

Thermal insulation

Acoustic insulation

Environmentally friendly

B500c steel of Greek origin.

The B500c reinforced concrete steel is the primary material ensuring the safety and strength of a reinforced concrete construction. Its main purpose is to provide resistance and stability to the structure, especially in cases of intense seismic activity.

The reinforcement steel (bars, meshes) strengthens the building’s load-bearing frame and prevents the concrete from cracking or breaking at critical points such as columns, beams, and slabs.

During seismic activity, the steel absorbs seismic energy and prevents damage to the building.

Due to the high seismicity of the region, strict adherence to the structural engineer’s study is required, along with the use of high-strength and ductile steel, according to ELOT 1421 standards.

The B500c steel used by the company is sourced from the Greek company SIDENOR, of excellent quality, meeting modern specifications, and is distinguished by its strength, ductility, flexibility, and weldability, in accordance with anti-seismic regulations and the new ELOT 1421 standard.

Concrete C25/30

Characteristics:

Resistant to various aggressive exposure environments.

Excellent mechanical strength

Excellent compressive and tensile strength

High quality and durability

Reduced water permeability, ideal for coastal environments

Resistant to surface wear

Resistant to chemical attacks

The strict provisions of the Concrete Technology Regulation of 1997 (C.T.R. 97) specify the minimum dosages of raw materials depending on the specific application of the concrete (such as workability, strength, plasticity, exposure environment, performance, and service life of the construction). The different properties of the raw materials mixed in concrete production (mass, volume, physico-chemical characteristics) make concrete production an extremely complex and sophisticated process.

Due to the high seismic activity in our country, both the production process and the final incorporation of the concrete into constructions are governed by the highly demanding Concrete Technology Regulation (C.T.R. 97), which is currently in effect, covering the requirements for modern, safe, and earthquake-resistant constructions.

Used as a primer for surfaces before applying a bituminous membrane.

Dries quickly, forming a uniform, hard, and flexible final layer. Its low-viscosity composition allows it to penetrate the pores of the surface and create excellent adhesion to construction materials. Resistant to dilute acid and alkaline solutions as well as seawater.

Outstanding durability over time.

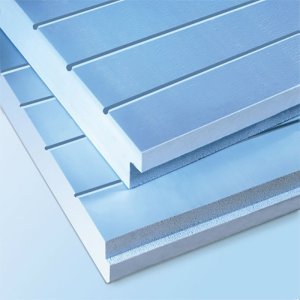

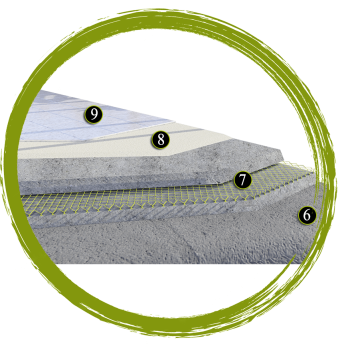

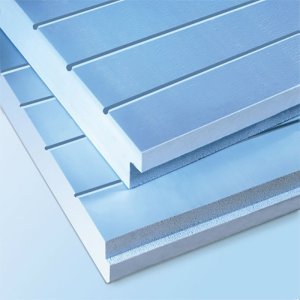

EXTRUDED POLYSTYRENE

High-performance, with thermal conductivity λ up to 0.030 W/m·K, suitable for insulating concrete elements.

Characteristics:

Excellent thermal insulation performance

Zero moisture absorption

High energy savings

Cost-effective solution

Environmentally friendly

High load-bearing capacity

Easy to install

High compressive strength

Applications:

Thermal insulation of concrete elements

Cement-based surface layer material with embedded fiberglass mesh

FIBERGLASS MESH

Characteristics:

Alkali-resistant

Crack-resistant

Alkali-resistant mesh for the base layer of the external thermal insulation system made of fiberglass. Complies with the European guideline ETAG 004.

User- and environmentally-friendly. High tensile strength. Strong resistance to elastic deformation, slippage, and displacement.

A low-viscosity, cast, elastic membrane, polyurethane-based, single-component. It cures with atmospheric moisture, forming a monolithic waterproof membrane with excellent adhesion across the entire surface and a service life of up to 25 years.

It consists of pure, elastomeric, hydrophobic polyurethane resin, combined with special inorganic additives, providing exceptional resistance to weathering, chemicals, UV radiation, mechanical stress, and thermal loads.

Advantages:

Excellent point-to-point adhesion and waterproofing

Seamless membrane

High resistance to UV radiation

Water vapor permeable

Resistant to hydrolysis and microorganisms

Chemical and abrasion resistance

Exceptional elasticity

Allows direct bonding of covering materials (e.g., tiles) onto the membrane

Easy to repair and maintain

In drywall constructions, the metal framework is the supporting system created from pre-formed metal profiles (usually galvanized steel) onto which the plasterboards are screwed.

This framework is responsible for transferring loads (weight of plasterboards, doors, cabinets, etc.), ensuring the mechanical stability of the construction, and providing geometric accuracy (flatness, vertical alignment, and level surfaces).

The metal profiles are intended for dry construction systems and are the ideal solution for false ceilings and partition walls using plasterboards. They offer corrosion resistance, long lifespan, and structural stability.

Components:

Horizontal profiles (guides – UW or UD depending on the application): Fastened to the floor, ceiling, and walls.

Vertical profiles (studs – CW or CD): Placed at regular intervals and connected to the horizontal guides.

Depending on the type of construction (wall, false ceiling, or wall cladding), different types and cross-sections of profiles are selected.

KNAUF PLASTERBOARD – INTERNAL WALL CLADDING MADE OF NATURAL GYPSUM

Application: Internal wall cladding for prefabricated houses or concrete houses, applicable to both load-bearing and non-load-bearing elements in dry construction systems.

Advantages:

Non-combustible, fire-resistant: Class A1

Breathable (water vapor permeability)

Flexible

Minimal expansion and contraction with changes in climatic conditions

Environmentally friendly due to natural gypsum raw material

Easy to work with and repair in case of damage

Provides thermal and acoustic insulation

Thermal conductivity: λ = 0.21 W/(m·K)

Sound absorption coefficient: A

Type: Plasterboard according to DIN 18180 GKB, EN 520 A, ELOT 784

Description:

Knauf plasterboard with λ = 0.21 W/(m·K), made from natural gypsum, porous and breathable, allowing the wall to “breathe.” Easy to repair if damaged. It is a modern material for interior construction, offering thermal insulation, acoustic insulation, and seismic resistance.

For bathrooms, a special moisture-resistant Knauf Guardex plasterboard is used, containing additives that reduce water absorption.

Thickness: 12.5 mm

Product Certification: EN 520:2004 + A1:2009, complying with German standard DIN 18180, European EN 520, and Greek ELOT 784

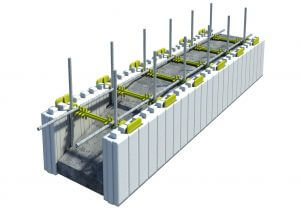

ANDROULAKIS ICF INTERMEDIATE FLOOR

B500c steel of Greek origin.

The B500c reinforced concrete steel is the primary material ensuring the safety and strength of a reinforced concrete construction. Its main purpose is to provide resistance and stability to the structure, especially in cases of intense seismic activity.

The reinforcement steel (bars, meshes) strengthens the building’s load-bearing frame and prevents the concrete from cracking or breaking at critical points such as columns, beams, and slabs.

During seismic activity, the steel absorbs seismic energy and prevents damage to the building.

Due to the high seismicity of the region, strict adherence to the structural engineer’s study is required, along with the use of high-strength and ductile steel, according to ELOT 1421 standards.

The B500c steel used by the company is sourced from the Greek company SIDENOR, of excellent quality, meeting modern specifications, and is distinguished by its strength, ductility, flexibility, and weldability, in accordance with anti-seismic regulations and the new ELOT 1421 standard.

B500c steel of Greek origin.

The B500c reinforced concrete steel is the primary material ensuring the safety and strength of a reinforced concrete construction. Its main purpose is to provide resistance and stability to the structure, especially in cases of intense seismic activity.

The reinforcement steel (bars, meshes) strengthens the building’s load-bearing frame and prevents the concrete from cracking or breaking at critical points such as columns, beams, and slabs.

During seismic activity, the steel absorbs seismic energy and prevents damage to the building.

Due to the high seismicity of the region, strict adherence to the structural engineer’s study is required, along with the use of high-strength and ductile steel, according to ELOT 1421 standards.

The B500c steel used by the company is sourced from the Greek company SIDENOR, of excellent quality, meeting modern specifications, and is distinguished by its strength, ductility, flexibility, and weldability, in accordance with anti-seismic regulations and the new ELOT 1421 standard.

PVC is harder and more durable than steel and can withstand very low and very high temperatures.

PVC is a thermoplastic polymer and can produce products with a wide range of mechanical properties (from flexible to rigid), has chemical resistance, and is difficult to ignite.

Smart Form is a material produced from solid polystyrene beads. It is rigid, environmentally friendly, has excellent thermal and acoustic insulation properties, is resistant to moisture, does not decompose, and consequently has a lifelong durability.

The ICF formwork provides double insulation for the building and remains as permanent formwork. Therefore, there is no need to wait for the concrete to harden, which significantly reduces construction time.

The ICF formwork technology also enables us to construct a building entirely from reinforced concrete, making the structure monolithic, solid, unified, and resistant to high seismic activity.

Characteristics:

Exceptional density

Self-extinguishing material (does not propagate flames)

Manufactured according to European standards EN 13163

Thermal insulation

Acoustic insulation

Environmentally friendly

B500c steel of Greek origin.

The B500c reinforced concrete steel is the primary material ensuring the safety and strength of a reinforced concrete construction. Its main purpose is to provide resistance and stability to the structure, especially in cases of intense seismic activity.

The reinforcement steel (bars, meshes) strengthens the building’s load-bearing frame and prevents the concrete from cracking or breaking at critical points such as columns, beams, and slabs.

During seismic activity, the steel absorbs seismic energy and prevents damage to the building.

Due to the high seismicity of the region, strict adherence to the structural engineer’s study is required, along with the use of high-strength and ductile steel, according to ELOT 1421 standards.

The B500c steel used by the company is sourced from the Greek company SIDENOR, of excellent quality, meeting modern specifications, and is distinguished by its strength, ductility, flexibility, and weldability, in accordance with anti-seismic regulations and the new ELOT 1421 standard.

Concrete C25/30

Characteristics:

Resistant to various aggressive exposure environments.

Excellent mechanical strength

Excellent compressive and tensile strength

High quality and durability

Reduced water permeability, ideal for coastal environments

Resistant to surface wear

Resistant to chemical attacks

The strict provisions of the Concrete Technology Regulation of 1997 (C.T.R. 97) specify the minimum dosages of raw materials depending on the specific application of the concrete (such as workability, strength, plasticity, exposure environment, performance, and service life of the construction). The different properties of the raw materials mixed in concrete production (mass, volume, physico-chemical characteristics) make concrete production an extremely complex and sophisticated process.

Due to the high seismic activity in our country, both the production process and the final incorporation of the concrete into constructions are governed by the highly demanding Concrete Technology Regulation (C.T.R. 97), which is currently in effect, covering the requirements for modern, safe, and earthquake-resistant constructions.

Cement-based surface layer material with embedded fiberglass mesh

FIBERGLASS MESH

Characteristics:

Alkali-resistant

Crack-resistant

Alkali-resistant mesh for the base layer of the external thermal insulation system made of fiberglass. Complies with the European guideline ETAG 004.

User- and environmentally-friendly. High tensile strength. Strong resistance to elastic deformation, slippage, and displacement.

A low-viscosity, cast, elastic membrane, polyurethane-based, single-component. It cures with atmospheric moisture, forming a monolithic waterproof membrane with excellent adhesion across the entire surface and a service life of up to 25 years.

It consists of pure, elastomeric, hydrophobic polyurethane resin, combined with special inorganic additives, providing exceptional resistance to weathering, chemicals, UV radiation, mechanical stress, and thermal loads.

Advantages:

Excellent point-to-point adhesion and waterproofing

Seamless membrane

High resistance to UV radiation

Water vapor permeable

Resistant to hydrolysis and microorganisms

Chemical and abrasion resistance

Exceptional elasticity

Allows direct bonding of covering materials (e.g., tiles) onto the membrane

Easy to repair and maintain

EXTRUDED POLYSTYRENE

High-performance, with thermal conductivity λ up to 0.030 W/m·K, suitable for insulating concrete elements.

Characteristics:

Excellent thermal insulation performance

Zero moisture absorption

High energy savings

Cost-effective solution

Environmentally friendly

High load-bearing capacity

Easy to install

High compressive strength

Applications:

Thermal insulation of concrete elements

In drywall constructions, the metal framework is the supporting system created from pre-formed metal profiles (usually galvanized steel) onto which the plasterboards are screwed.

This framework is responsible for transferring loads (weight of plasterboards, doors, cabinets, etc.), ensuring the mechanical stability of the construction, and providing geometric accuracy (flatness, vertical alignment, and level surfaces).

The metal profiles are intended for dry construction systems and are the ideal solution for false ceilings and partition walls using plasterboards. They offer corrosion resistance, long lifespan, and structural stability.

Components:

Horizontal profiles (guides – UW or UD depending on the application): Fastened to the floor, ceiling, and walls.

Vertical profiles (studs – CW or CD): Placed at regular intervals and connected to the horizontal guides.

Depending on the type of construction (wall, false ceiling, or wall cladding), different types and cross-sections of profiles are selected.

KNAUF PLASTERBOARD – INTERNAL WALL CLADDING MADE OF NATURAL GYPSUM

Application: Internal wall cladding for prefabricated houses or concrete houses, applicable to both load-bearing and non-load-bearing elements in dry construction systems.

Advantages:

Non-combustible, fire-resistant: Class A1

Breathable (water vapor permeability)

Flexible

Minimal expansion and contraction with changes in climatic conditions

Environmentally friendly due to natural gypsum raw material

Easy to work with and repair in case of damage

Provides thermal and acoustic insulation

Thermal conductivity: λ = 0.21 W/(m·K)

Sound absorption coefficient: A

Type: Plasterboard according to DIN 18180 GKB, EN 520 A, ELOT 784

Description:

Knauf plasterboard with λ = 0.21 W/(m·K), made from natural gypsum, porous and breathable, allowing the wall to “breathe.” Easy to repair if damaged. It is a modern material for interior construction, offering thermal insulation, acoustic insulation, and seismic resistance.

For bathrooms, a special moisture-resistant Knauf Guardex plasterboard is used, containing additives that reduce water absorption.

Thickness: 12.5 mm

Product Certification: EN 520:2004 + A1:2009, complying with German standard DIN 18180, European EN 520, and Greek ELOT 784