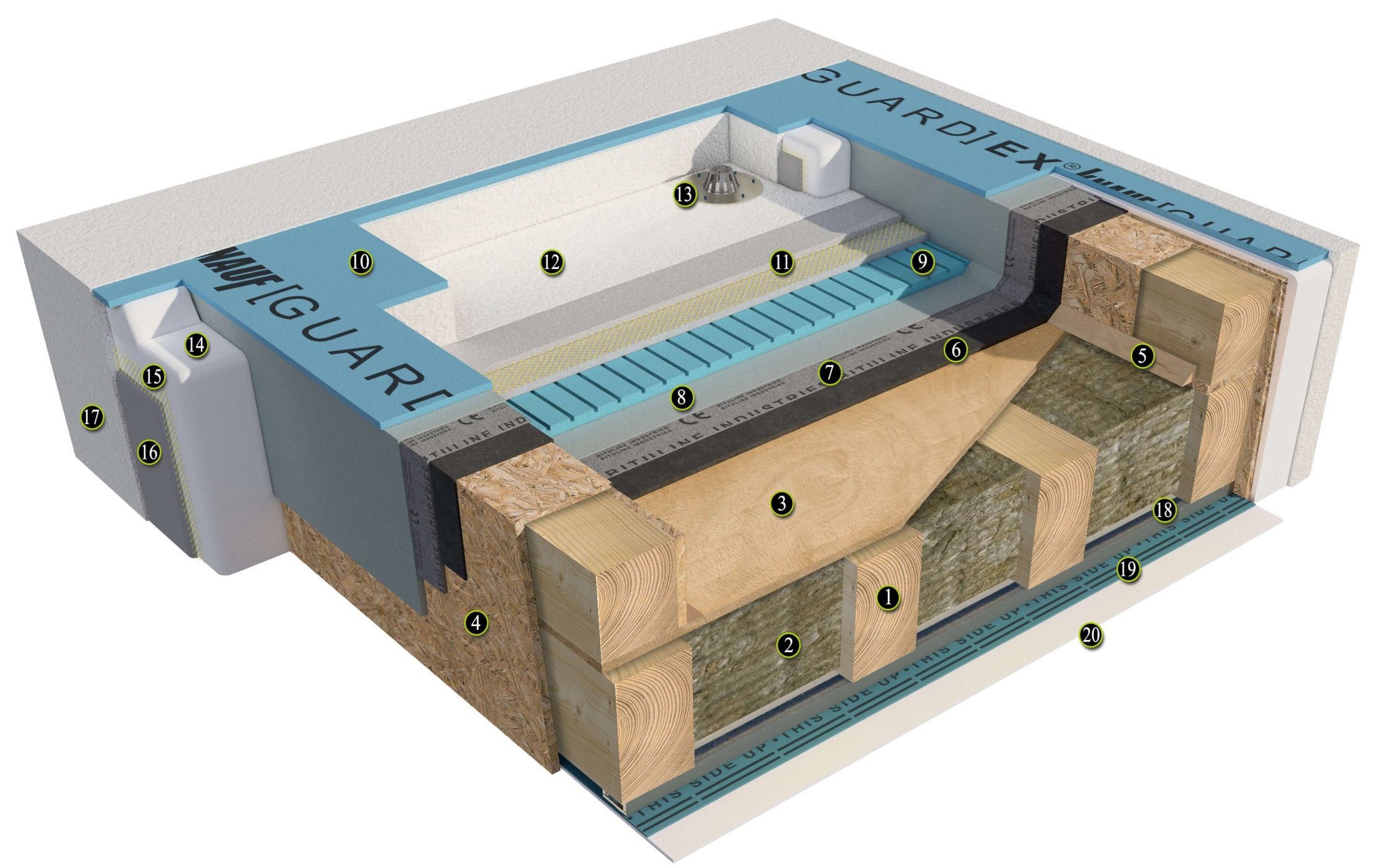

KNAUF GYPSUM BOARD – INTERIOR WALL CLADDING MADE OF NATURAL GYPSUM

Application: interior wall cladding in prefabricated homes – concrete houses, for load-bearing & non-load-bearing dry construction elements.

ADVANTAGES

- Non-combustible, fire resistance class A1

- Breathable (water vapor permeability)

- Flexible

- Extremely minimal expansion and contraction under changing climatic conditions

- Ecological due to the raw material, natural mineral gypsum

- Easy to process (very easy to repair in case of damage)

- Provides thermal insulation and sound insulation. Thermal conductivity coefficient λ: 0.21 W/(m·K)

Sound absorption coefficient A

Gypsum board type according to DIN 18180 GKB, EN 520 A, ELOT 784

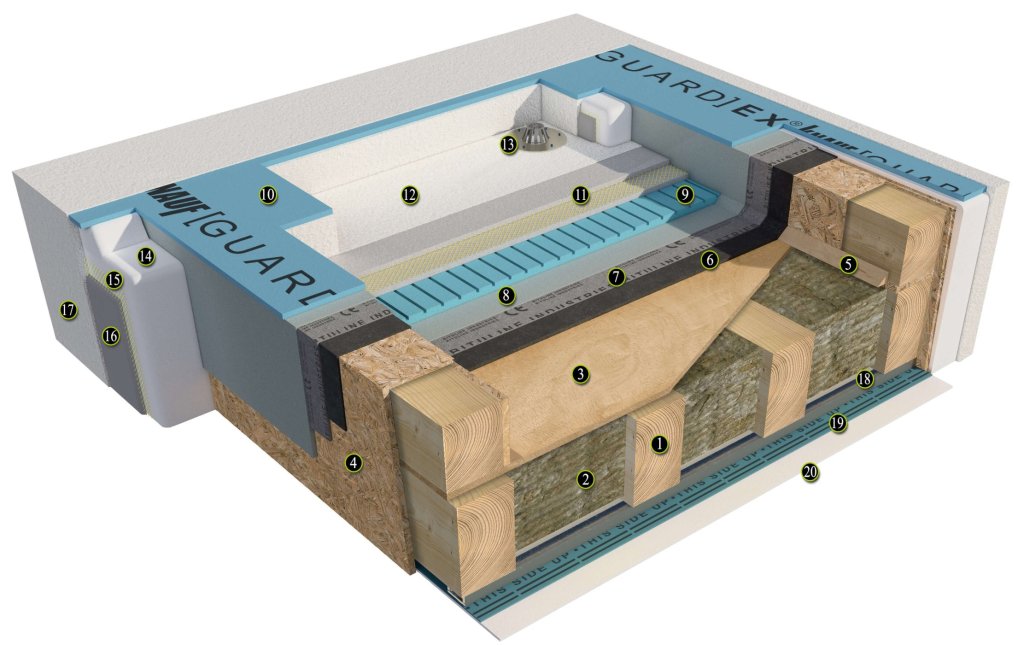

Gypsum board λ = 0.21 (W/mK) by Knauf, made of natural gypsum, a porous and breathable material that allows the wall structure to breathe. It is very easy to repair in case of damage. It is the most modern material for interior construction. It provides thermal insulation, sound insulation, and seismic resistance. In bathrooms, a special moisture-resistant fiberboard Knauf Guardex is installed, which contains additives that reduce its water absorption.

Thickness: 12.5 mm

Product Certification: EN 520:2004 + A1:2009

Compliance with German standard DIN 18180

Europe: EN 520

Greece: ELOT 784

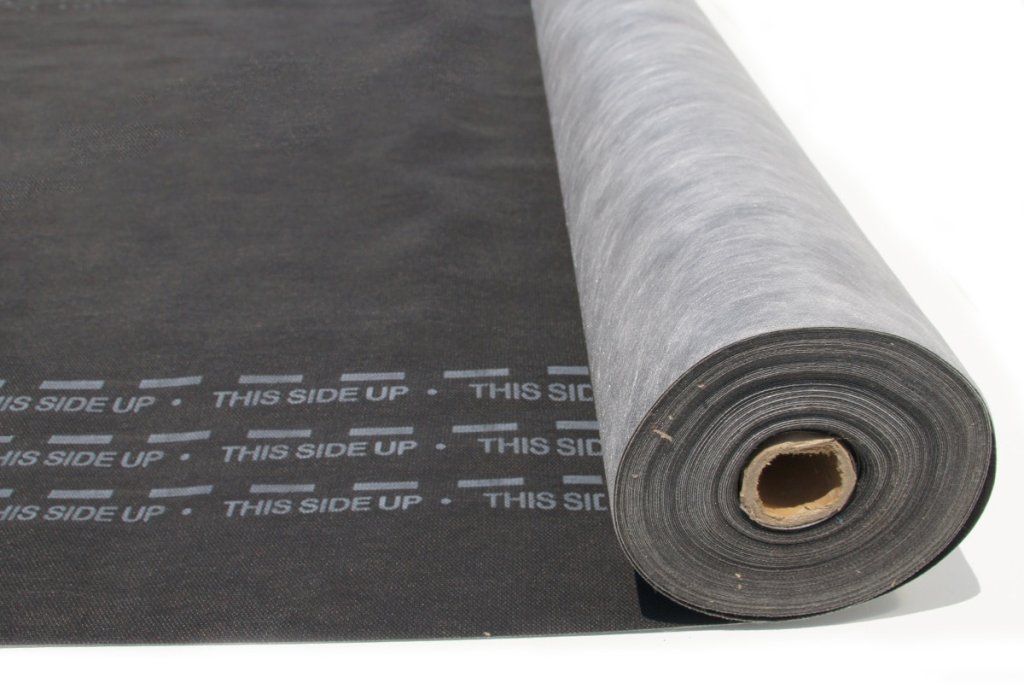

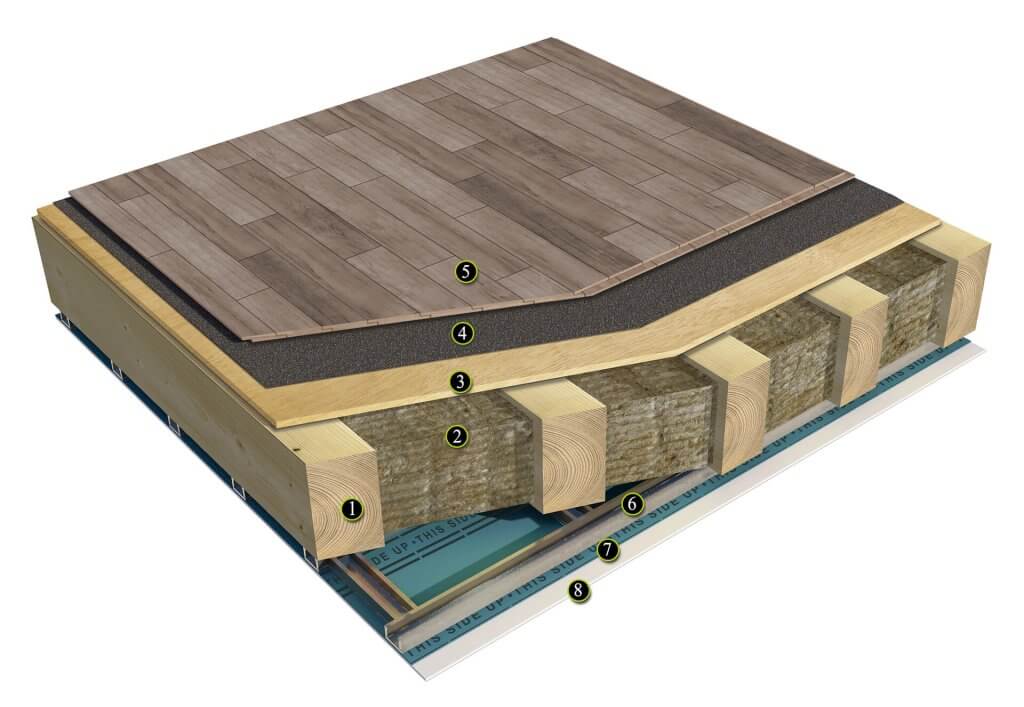

VAPOR BARRIER MEMBRANE

A membrane that provides moisture protection to the wall system λ = 0.3 W/(m·K)

It provides insulation to the structure and protects against moisture, preventing the formation of water vapor that could gradually cause future damage to the construction.

NATURAL MINERAL WOOL – ULTRACOUSTIC P HIGH SOUND ABSORPTION PARTITION PANELS

Natural Mineral Wool panels with high sound absorption, free of petroleum-based chemical additives & formaldehyde, resistant to microorganisms, bacteria & mold.

Water-resistant

Breathable (allows vapor diffusion)

Application: Thermal and acoustic insulation of partitions and walls in prefabricated homes & ICF concrete houses

Thermal conductivity coefficient λ = 0.037 W/mK.

Non-combustible material, fire classification A1

ADVANTAGES

- Excellent resistance and reaction to fire – Euroclass A1

- Excellent mechanical strength

- Outstanding acoustic performance

Thermal insulating, fire-protective, recyclable material

- CE: MW-EN 13164-T4-AF5

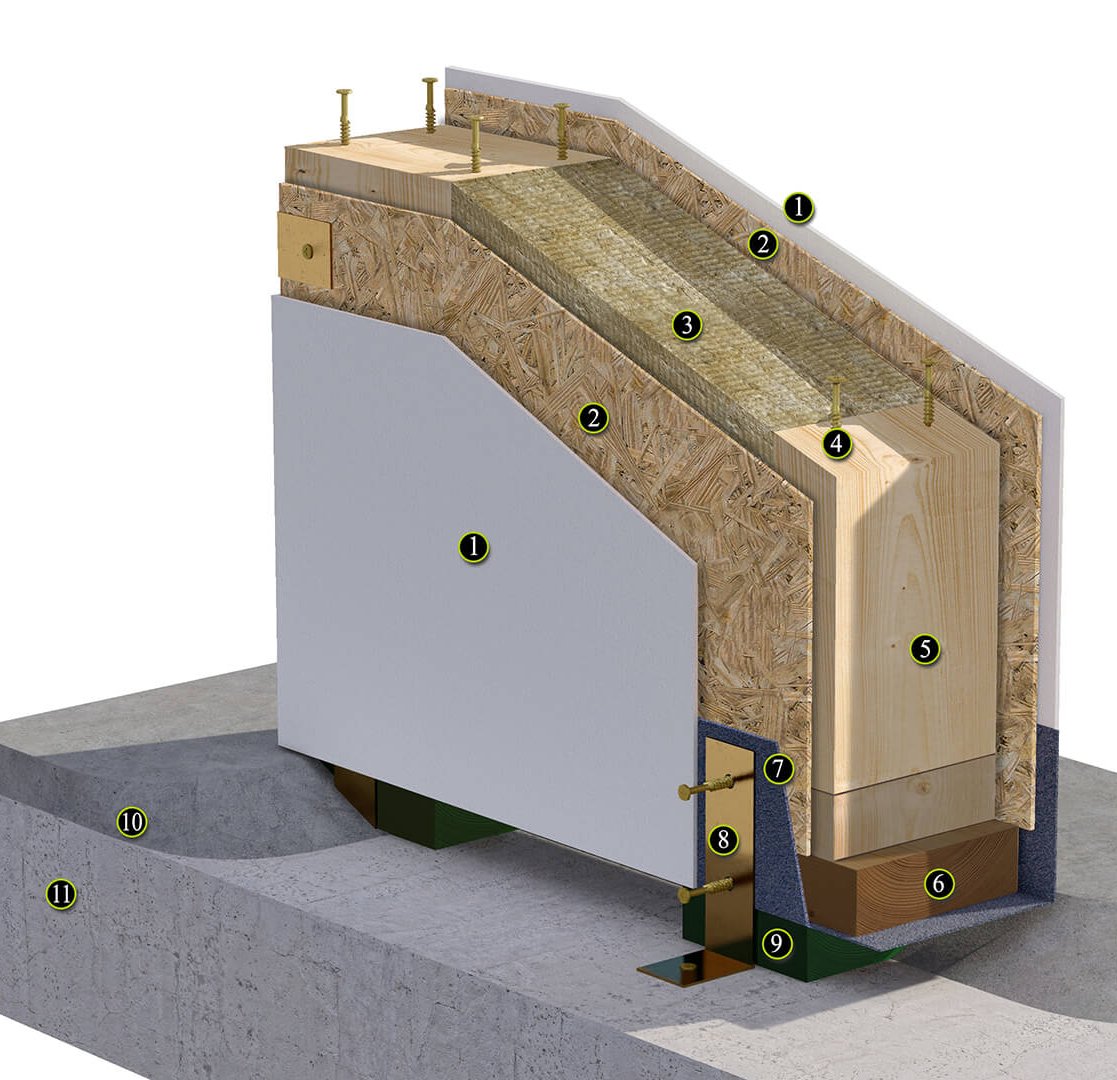

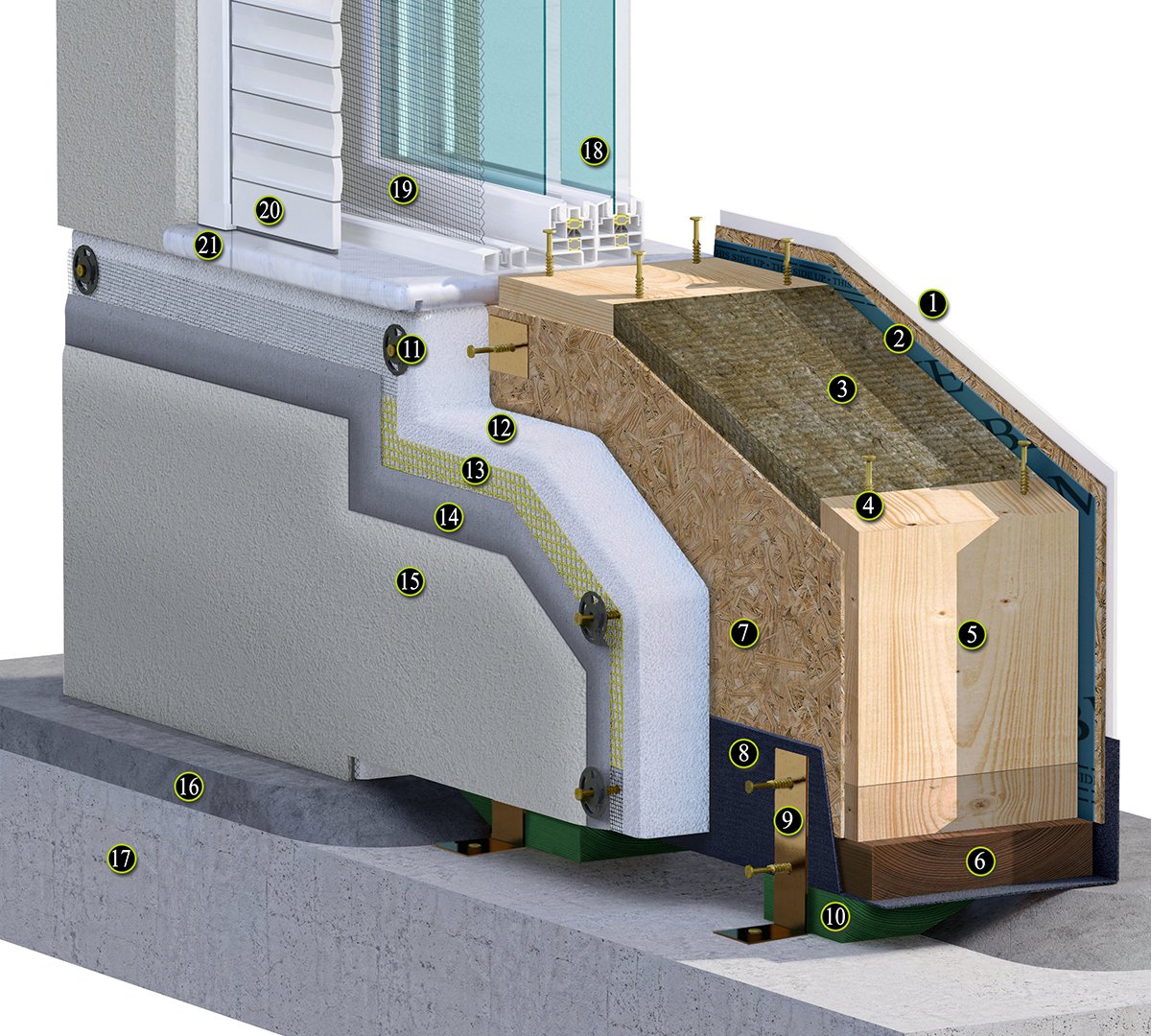

CONNECTION BOLT

APPLICATION: Screw-fastened wall technology using TORX screws & bolts from the leading German manufacturer Wurth.

ADVANTAGES

- The use of bolts does not allow loosening of the connections over time.

- Provides stronger and higher-quality assembly of the wall structure.

- Our scientific department developed joinery systems designed to reinforce the load-bearing structure & create a fully seismic-resistant construction capable of withstanding high stress loads.

MECHANICAL ANCHOR PLUG

- Mechanical anchor plug, which is part of the Androulakis thermal insulation system.

ANDROULAKIS, as a pioneering company in the sector, uses the finest raw materials, as only it knows how, uncompromisingly! Our priority is the initial construction stage—the load-bearing structure—which determines the building’s structural stability, thermal insulation, and moisture protection, all contributing to the building’s longevity. Therefore, the best choice for constructing the load-bearing structure is none other than the use of SWEDISH & SCANDINAVIAN TIMBER λ = 0.12 (W/mK).

Application: Use of Swedish timber, the primary construction material for the load-bearing structure in prefabricated homes.

ADVANTAGES

- Strength class C24, high mechanical strength, according to EN 338. The C class rating indicates bending strength.

- Kiln-dried: The drying process imparts significant advantages to the timber. Drying occurs uniformly and at a slow moisture release rate, resulting in strength up to 80% higher than conventional timber. Residual moisture is 12–15% to maintain elasticity, making it resistant to microorganisms and ideal for structural construction.

- VACUUM TREATMENT: Timber is treated with natural insect disinfestation without chemical impregnation. The impregnation is performed using the full-cell method (vacuum-pressure-vacuum). The protective treatment of the wood provides protection against decay fungi and insects, improves dimensional stability, enhances physical and mechanical properties, and increases fire resistance.

- Planed, meaning it has perfectly flat surfaces, which, combined with factory joinery, achieve perfect alignment & zero gaps in the frame sections.

- Thermal insulation: Wood is a natural material that acts as an excellent natural regulator of temperature and humidity inside the house, providing natural thermal insulation properties superior to any other building material.

Organic: It contains no chemical additives, as Swedish timber is governed by strict regulations regarding production, export, and commercial use.

High seismic resistance: Houses with a wooden load-bearing frame exhibit high seismic resistance, due to the advantages of wood as a material, its high mechanical strength, high density relative to its weight, and elasticity, which allows the absorption of seismic loads at the connections of the frame elements. Additionally, wood does not retain seismic memory and withstands consecutive seismic vibrations with varying accelerations (g: 0.5 to 0.9) and directions, making the house fully earthquake-resistant.

.

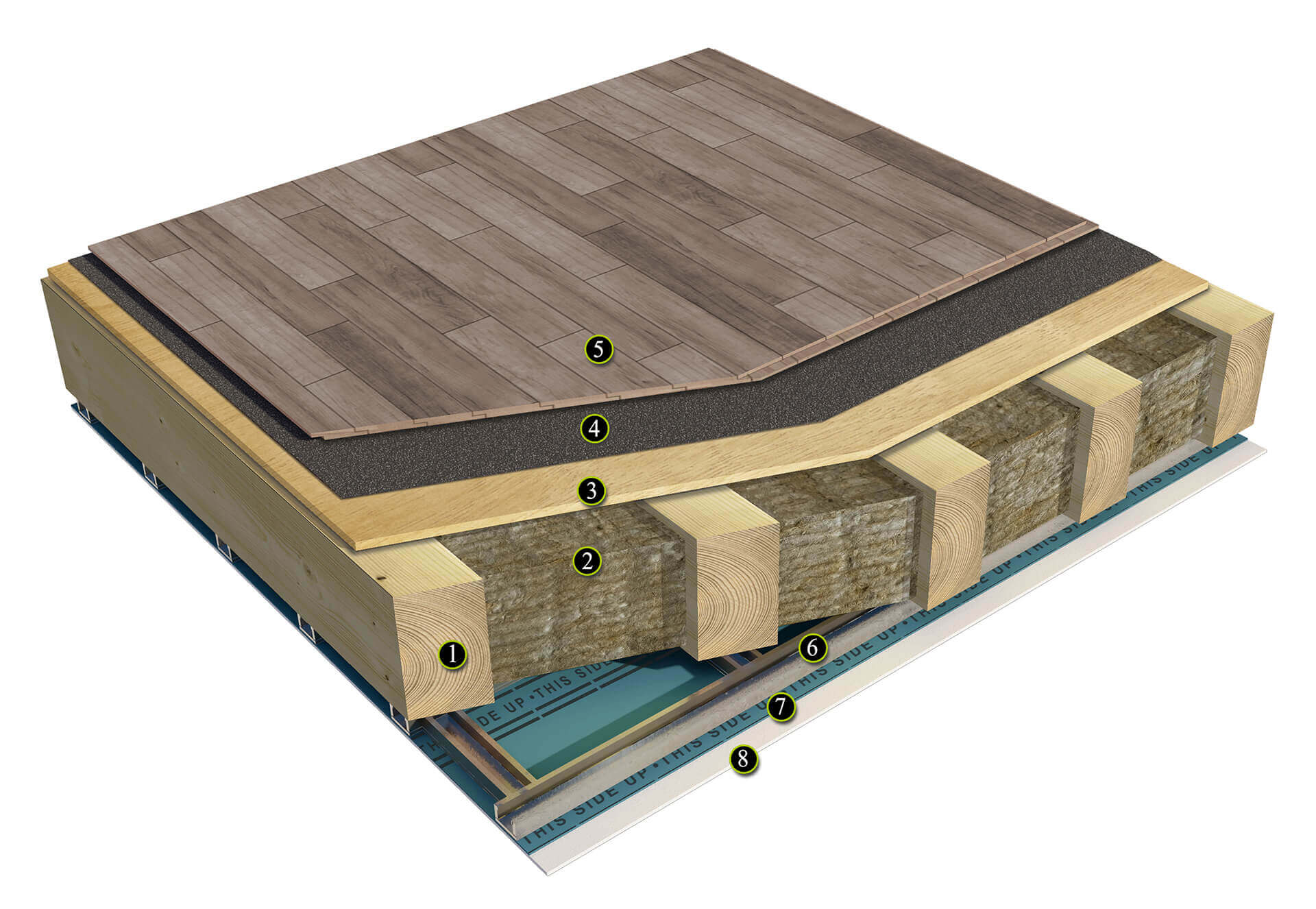

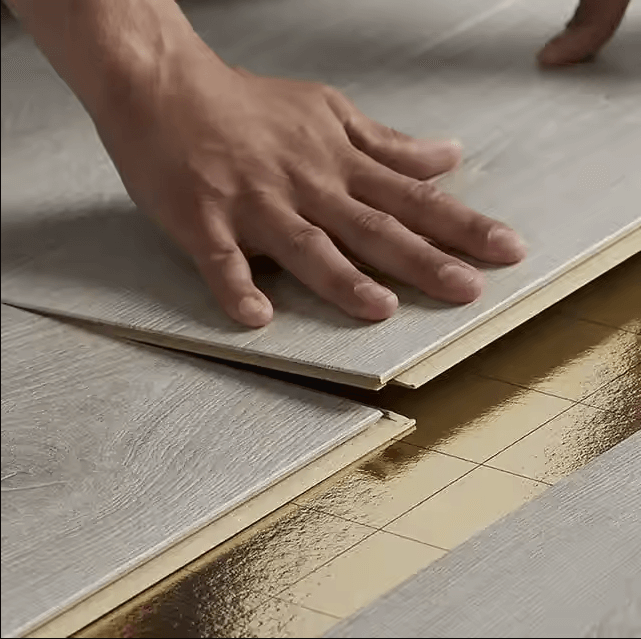

EGGER OSB 3 (Oriented Strand Board)

OSB – Oriented Strand Board, LP λ = 0.13 (W/mK), thickness: 11.1 mm, is an engineered wood material. Its uniformity makes it ideal for construction surfaces. It consists of long wood strands bonded together with a synthetic resin. The waterproof and heat-resistant resin bonds combine with the wood strands to improve internal stability, rigidity, and moisture resistance.

Application: walls, intermediate floors, roofs

Among all structural elements of a house, the exterior walls are most exposed to changing weather conditions. Protection from summer overheating, winter thermal insulation, and adequate sound insulation are reliably achieved using EGGER OSB 3 panels.

Advantages of EGGER OSB 3:

- EGGER OSB 3 is the recommended surface for applications in humid conditions (walls, intermediate floors, roofs)

- Offers increased moisture resistance and safety in case of unexpected wetting, reducing the risk of warping or loosening of fasteners.

- According to European standard EN 13986, EGGER OSB 3 is classified as normally combustible, with moderate smoke emission and absence of flaming particles.

- Compliant with Eurocode 5 requirements for external structural elements, such as exterior walls.

- Provides protection against fire and moisture.

- Higher density than plywood, ensuring longer service life.

- Fully waterproof (class 3) with strong cohesion due to its homogeneous structure; performance is not affected by moisture.

- Excellent thermal and acoustic insulation properties.

- High mechanical strength contributes to improved structural stability of the building.

- Hygiene class E1, recyclable, and environmentally friendly.

It meets European standard EN 300, with maximum mechanical strength, making it one of the best building materials available.

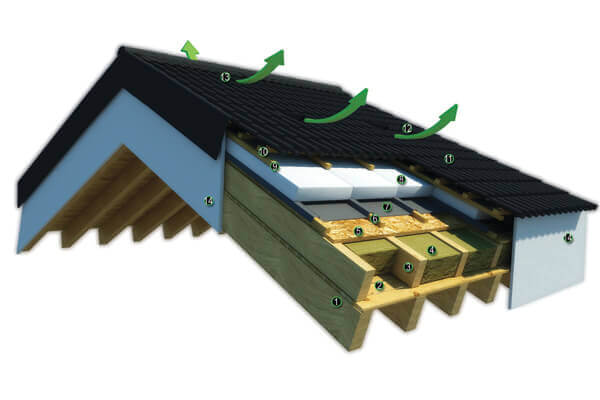

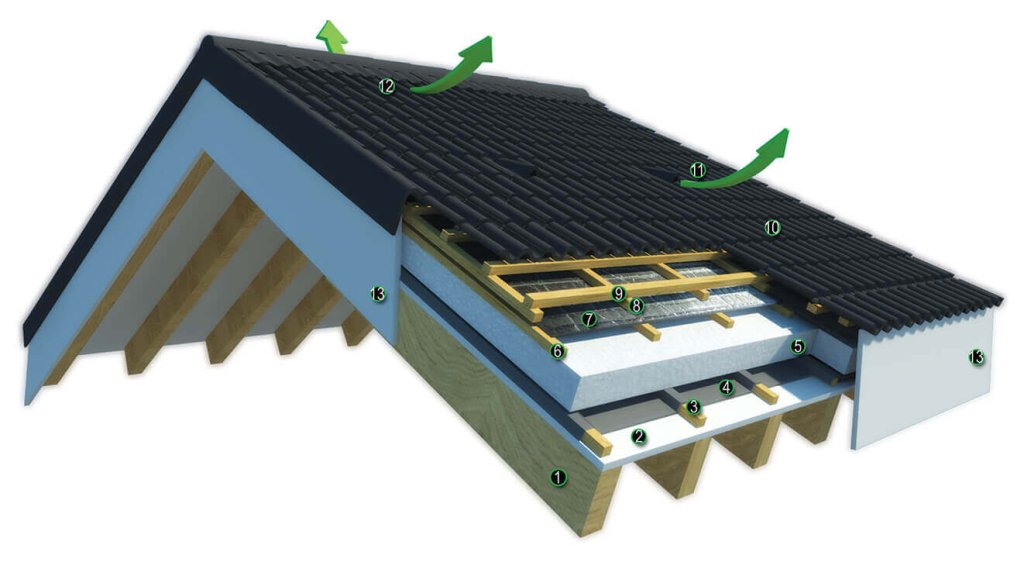

BREATHABLE ASPHALT MEMBRANE

- It is a specialized waterproofing membrane, partially vapor-permeable, featuring a unique combination of double polypropylene fabric and asphalt.

Application: Waterproofing of roofs & walls

ADVANTAGES

- Provides complete waterproofing.

- High mechanical strength, does not tear or puncture.

- Resistant to high temperatures.

- Prevents the accumulation of water vapor.

- Meets EN 1110 and EN 12310 standards.

METAL SUPPORT ANGLES

- The wall structure is fully connected to the foundation, creating a completely “tied” construction.

Once the walls are manufactured and inspected at the factory, they are transported to the site and anchored to the reinforced concrete foundation using metal support angles. This locks the individual elements of the structure together, forming a unified monolithic body with enhanced mechanical strength and excellent seismic performance.

ADVANTAGES

- Increased mechanical strength

- Improved seismic resistance

Wall Base Waterproofing

We waterproof the base of the wall using impregnated NTR-A type beams.

This prevents the wall structure from being directly exposed to the concrete foundation, which may contain moisture drawn from the ground. In this way, the wall is protected from potential damage caused by moisture over time.

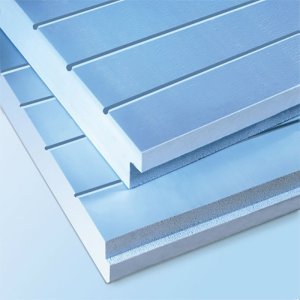

It is a material produced from solid polystyrene beads.

Application: External thermal insulation. EPS expanded polystyrene products are applied throughout a building, from the foundation to the roof.

ADVANTAGES

- Excellent thermal insulation properties

- Sound insulation properties, contributing to acoustic insulation of both airborne and impact noise.

- Rigid

- Non-toxic, produced without chemical additives

- Resistant to moisture, with low water vapor diffusion resistance, allowing the material to “breathe” and prevent condensation

- Structurally stable and does not decompose; EPS stability is maintained over time, with a lifelong durability

- Self-extinguishing, does not propagate flame; produced for building use as self-extinguishing (SE) with fire retardant integrated into the material

- Fully recyclable and environmentally friendly

- Manufactured according to European standard EN 13163

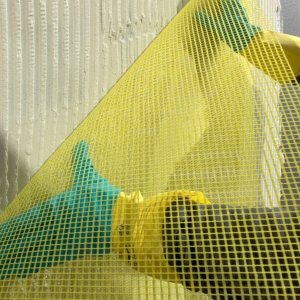

FIBERGLASS MESH

Characteristics

- Alkali-resistant

- Crack-resistant

Alkali-resistant mesh for the base layer of the external thermal insulation system, made from fiberglass. Complies with European guideline ETAG 004.

User- and environmentally-friendly. High tensile strength. Strong resistance to elastic deformation, slippage, and displacement.

Kappa 11 Base Coat by BAUER.

Provides exceptional adhesion, high resistance to shear stress, and ensures superior durability.

Finish coat, 5 mm thick, of colored fiber-reinforced inorganic MONOKAPA material by BAUER. It serves as the final layer of the Androulakis thermal insulation system.

Water vapor permeability: V2 EN 7783-2

Water absorption: W3 EN 1062-3

Thermal conductivity: λ = 0.7 W/(m·K) EN 1745

Features high elasticity, minimizing crack formation and providing excellent breathability. High resistance to algae and bacteria, with strong durability against rain. Outstanding performance under all weather conditions and UV exposure. Available in a wide range of colors with excellent color stability.

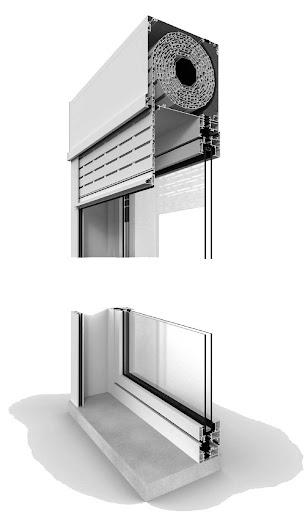

Here you can see detailed characteristics and types of Androulakis frames.

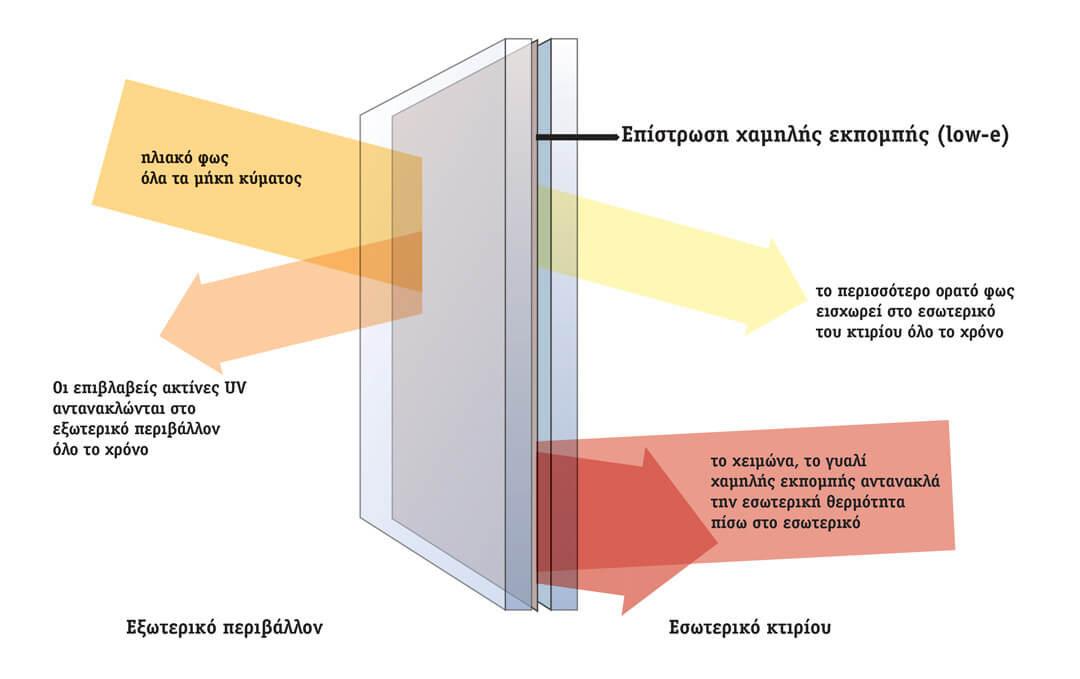

The “Energy Glass Panes” for all four seasons have the ability to reduce heat transfer from the warmer side to the cooler side (hence called Low-E glass). This capability helps retain the heat inside the house during winter and keep external heat out during summer, saving energy for heating or air conditioning.

This property of the “Energy Glass Panes” works under all weather conditions (cloudy or sunny), at all times of day (day and night), and throughout the year (winter and summer).